Mastering Concrete Cube Strength: Expert Tips and Techniques

Concrete cubes are essential components in various construction projects, serving as a crucial indicator of the material's strength and durability. Achieving optimal strength in concrete cubes requires meticulous attention to detail and adherence to specific techniques.

Understanding the Importance of Concrete Cube Strength

Before delving into the intricacies of casting concrete cubes, it's essential to understand why strength testing is crucial. Concrete cubes serve as a representative sample of the material used in construction projects, allowing engineers to assess its compressive strength accurately. This data is vital for ensuring the structural integrity and longevity of buildings, bridges, roads, and other infrastructure.

Selecting High-Quality Materials

The foundation of strong concrete cubes lies in the quality of materials used in the mixture. High-quality cement, aggregates, and water are essential for achieving optimal results. When selecting materials, it's imperative to consider factors such as particle size, grading, and moisture content to ensure uniformity and consistency in the concrete mixture.

Proven Mix Design Formulations

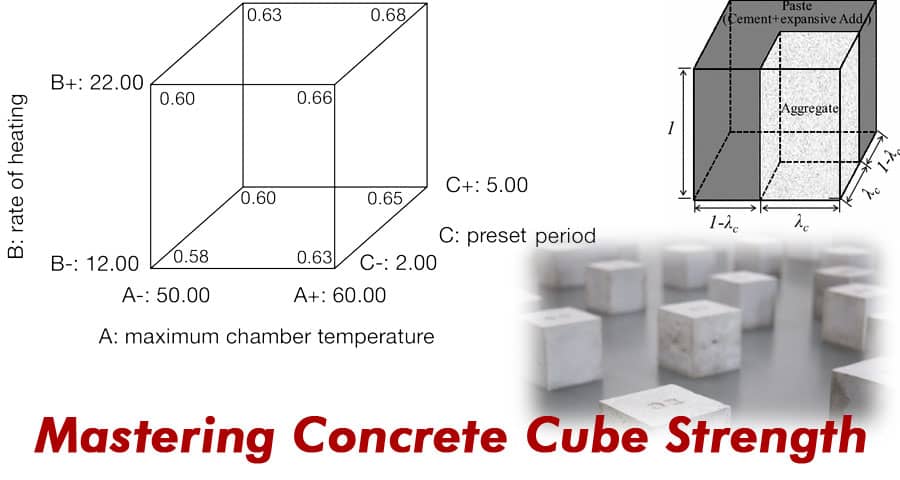

A well-formulated mix design is fundamental to achieving the desired strength in concrete cubes. Engineers employ proven formulations that balance the ratio of cement, aggregates, water, and admixtures to achieve the desired properties. Through meticulous testing and optimization, experts refine mix designs to meet specific project requirements and environmental conditions.

Precision in Casting Techniques

Casting concrete cubes with precision is paramount to ensuring accurate strength test results. Careful attention must be paid to every stage of the casting process, from preparing the mold to compacting the concrete and curing the specimens. Proper compaction eliminates voids and ensures uniform distribution of aggregates, contributing to enhanced strength and durability.

Optimizing Curing Conditions

Curing plays a pivotal role in the development of concrete cube strength. Optimal curing conditions, including temperature and moisture levels, are critical for facilitating the hydration process and promoting the formation of strong, durable concrete. Various curing methods, such as water curing, steam curing, and membrane curing, may be employed depending on project requirements and timeline.

Conducting Rigorous Testing Protocols

Once the concrete cubes have been cast and cured, rigorous testing protocols are employed to assess their compressive strength. Standardized testing procedures, such as ASTM C39/C39M, are followed to ensure consistency and accuracy in results. Testing may involve applying compressive loads to the specimens using hydraulic or mechanical testing machines until failure occurs.

Analyzing Test Results

The test results provide valuable insights into the performance of the concrete mixture and its suitability for the intended application. Engineers analyze the data to determine the compressive strength, modulus of elasticity, and other relevant properties. This information guides decision-making processes and may necessitate adjustments to mix designs or construction methodologies.

Continual Improvement and Quality Assurance

Achieving optimal concrete cube strength is an ongoing process that requires continual improvement and quality assurance measures. Engineers and concrete professionals collaborate to identify areas for enhancement and implement best practices to optimize performance and efficiency. Quality assurance protocols, including regular inspections and testing, are implemented to ensure adherence to standards and specifications.

For more information, please watch the following video tutorial

Conclusion

Mastering concrete cube strength is essential for ensuring the structural integrity and durability of construction projects. By adhering to proven techniques and best practices in material selection, mix design, casting, curing, testing, and quality assurance, engineers can achieve optimal results and safeguard the longevity of infrastructure. Continuous learning and innovation are key to staying abreast of advancements in concrete technology and maintaining excellence in construction practices.