Concrete Materials Test

Concrete consists of two main parts. The first part is the coarse and fine and the other part is glued between cement and water. The main elements are the coarse and fine aggregate, cement, water, and others that improve the characteristics of concrete. These components must be within definite percentage as they create a negative impact if the dosage is not correct. To obtain a concrete that conforms to the specifications, we must adjust the quality of each component in the concrete mix. Therefore, in this chapter the main necessary tests to cement, aggregate, water, and additives will be illustrated to obtain concrete with a high quality and to match the international standard and project specifications.

Concrete is weak under bending stress, so we use steel reinforcement to stand the bend stress, which increases the efficiency of concrete. Nowadays reinforced concrete is an vital element in the construction industry worldwide because it is low pricing in most cases than other alternatives and because of its easily formation in the early levels, which allows different architectural forms.

Steel is the most prior element in reinforced concrete structures as it carries almost all stresses on itself. Steel bars must be under a strict system of quality control to make sure they meet international standards and project specifications. These tests should be done with valid calibration devices to give accurate results.

The laboratory should look after the quality assurance system and the devices should be measured timely. Moreover, the samples must be collected correctly according to standard of rules given and all the necessary tests performed and review based on the quality system.

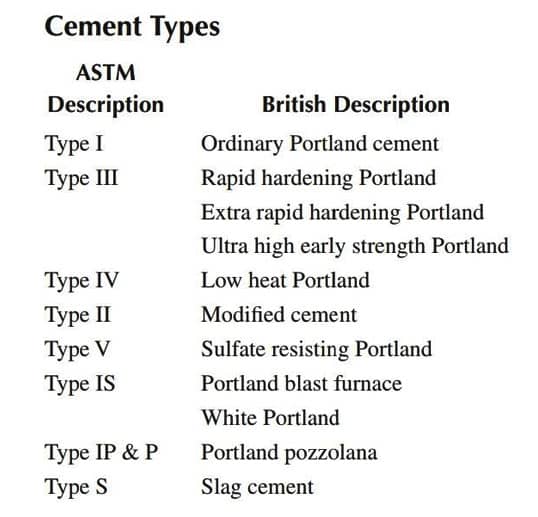

Cement Test by Sieve

The first class of cement affects the quality of the concrete industry in normally bases. A huge cement particle cannot fully react with water as water cannot reach a remaining core in the cement elements. The water cultivates the cement elements and they start to dry up, which causes an higher in temperature, which is the main reason for the forming of cracks and does not prevent stabilization of cement volume.

As a result, an increase in the cement element structure, reduces the strength of the same cement and increasing the first classiness of the cement will improve the workability and long time achievement with time and decrease the water moving upward to the concrete surface. Below chart presents the relation between concrete strength and the concrete first classiness at different ages. To perform this test, take a sample of 58 g of cement and shake it in a closed glass bottle for five minutes and then revolve the sample gently using dry bar.

Put the sample in a closed bottle and leave it for ten minutes. Put the sample in 172 (92 microns) and move it, shaking the sieve horizontally and rotationally, then confirm finishing the sieve test when the rate of passing cement particles is not more than 0.8 g/min during the sieve process. Remove the elements carefully from the bottom of the sieve using a brush. Then, accumulate and weigh the remaining elements on the sieve .

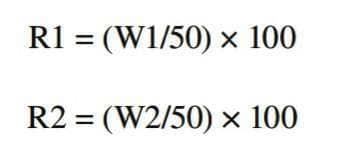

Repeat the same test with another sample. Then the accumulated weight for the second test is obtained . Calculate the values of the remaining samples through The ratio (R) is calculated by taking the average of R1 and R2 to the nearest 0.1%

and, in the case of divergent results of the two samples, more than 1%. Do the test a 3 time and take the average of the three results.

You can accept or refuse the cement based on the following condition

- For Portland cement the R must not exceed than 10%.

- For rapid hardening Portland cement the R must not go beyond 5%.