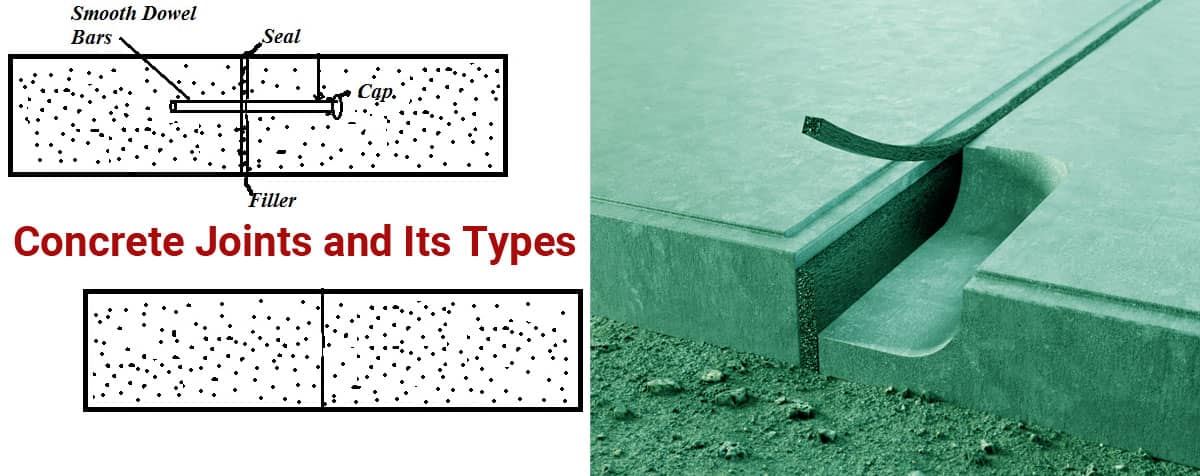

Concrete Joints and Its Types

Concrete Joints

Except in small jobs, it's impossible to put concrete in one continuous operation. Joints in concrete also are required for functional consideration of the structure. These joints are referred to as concrete joints. during this article, differing types of concrete joints are discussed.

Types Of Concrete Joints

Construction Joints.

These joints are provided where there's an opportunity in construction program. The concreting operation should be so planned that the work is completed in one operation. If, however, it's to be stopped before completion of the whole work, construction joints are provided. the situation of construction joints should be such it interferes minimum with the functional characteristics of the structure. the simplest locations for construction joints are as following:

Beam: Joint could also be located at mid-span or over the middle of the column in direction at right angles to the length of the beam.

Columns: Joints should be located a couple of cm below its junction with the beam.

Slab: Joints could also be placed at mid-span or directly over the middle of the beams, at right angles to the slab.

Formwork for construction joint should be placed at the top of every day's work.

Before new concreting is started, the concrete surface of hardened concrete should be cleaned, roughened, saturated with water, and applied cement grout. this may ensure proper bond between old and new concrete works. New concreting is started before the applied grout on old surface attains initial set.

Expansion Joints

These joints are provided to permit for expansion of the concrete, thanks to rise in temperature above the temperature during construction. Expansion joints also permit the contraction of the element. Expansion joints in India are provided at an interval of 18 to 21 m. The open gap of this joint varies between 2 cm and a couple of .5 cm. Sometimes, to transfer load from one slab to the adjacent slab

Contraction Joints.

These sorts of concrete joints are provided to permit contraction of the concrete. Contraction joints are spaced closer than expansion joints. These joints don't require any load transfer device because it are often achieved by the interlocking of aggregates. However, some agencies recommend use to dowel bars fully bonded in concrete.

Warping Joints.

Warping joints are provided to alleviate stresses induced thanks to warping effect. These joints also are referred to as hinged joints.