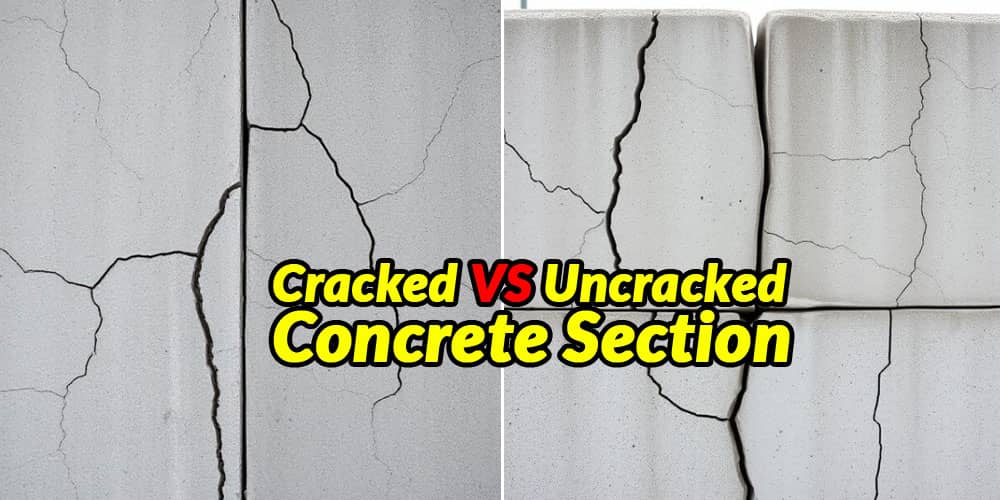

What is the Difference Between Cracked and Uncracked Concrete Section?

Understanding the Fundamentals of Concrete Behavior

Concrete, though robust and durable, is not impervious to stress. Its performance is largely categorized based on whether it is in a cracked or uncracked state. These distinctions play a critical role in structural design, serviceability, and long-term durability of reinforced concrete elements. A thorough understanding of the differences between these two states is essential for engineers, architects, contractors, and construction managers alike.

Definition of Cracked and Uncracked Concrete Sections

Uncracked Concrete Section

An uncracked concrete section refers to a state in which the tensile stresses within the concrete do not exceed the modulus of rupture - the point at which concrete fails in tension. In this state, concrete effectively resists both compressive and tensile forces, and the entire cross-section contributes to the moment of resistance. Reinforcement bars (rebar) embedded within the concrete may remain passive and are not actively carrying tensile stress.

Cracked Concrete Section

A cracked concrete section, on the other hand, occurs when tensile stresses exceed the tensile strength of concrete, leading to the formation of visible or microscopic cracks, particularly in tension zones. When concrete cracks, it can no longer resist tensile stresses. Instead, the steel reinforcement is solely responsible for carrying the tension. In such scenarios, the neutral axis shifts, and only the compressed concrete and tensile reinforcement contribute to the moment capacity.

Key Differences Between Cracked and Uncracked Concrete Sections

1. Tensile Stress Capacity

- Uncracked Concrete: Capable of resisting limited tensile stresses due to its inherent material properties.

- Cracked Concrete: Tensile stresses are entirely transferred to the reinforcing steel, as cracked concrete cannot resist tension.

2. Neutral Axis Position

- Uncracked Section: The neutral axis is located at a higher position since the full cross-section is effective.

- Cracked Section: The neutral axis drops as the tension side loses its stiffness due to cracking.

3. Moment of Inertia

- Uncracked: Higher moment of inertia, leading to reduced deflection under load.

- Cracked: Significantly reduced moment of inertia, resulting in increased deflection and curvature.

4. Serviceability Performance

- Uncracked Sections: Offer better serviceability, including control over deflection and cracking.

- Cracked Sections: Require careful design to ensure crack widths remain within acceptable limits for durability and aesthetic reasons.

5. Stiffness

- Uncracked Concrete: The entire section contributes to stiffness.

- Cracked Concrete: Only the compression zone and reinforcement steel contribute, reducing overall stiffness.

Cracking in Reinforced Concrete: Causes and Implications

Cracks typically form due to a combination of tensile stress, shrinkage, thermal expansion, loading conditions, and creep. In reinforced concrete, cracking is often expected and even accounted for during design, especially in flexural members like beams and slabs. However, the presence of cracks can lead to:

- Ingress of moisture and chemicals, potentially causing corrosion of reinforcement.

- Reduction in stiffness and load-carrying capacity.

- Aesthetic concerns in visible architectural surfaces.

Design Considerations for Cracked and Uncracked Sections

Flexural Design

In regions where cracking is expected, such as in bending zones of beams, design assumes a cracked section. The analysis uses the transformed section method or equivalent stiffness models to determine behavior under service loads.

Shear Design

Concrete is relatively strong in compression but weak in shear and tension. Cracks can initiate shear failure. Therefore, shear reinforcement is designed considering potential crack formation, particularly in regions with high shear forces.

Serviceability Limit States (SLS)

Uncracked concrete is generally desired under service load conditions to ensure comfort, durability, and structural integrity. For this reason, engineers aim to limit stress levels to keep sections uncracked under normal usage.

Crack Control and Reinforcement Detailing

To maintain serviceability and ensure structural performance, crack control is essential. This includes:

- Proper placement of reinforcement to resist tension.

- Use of minimum reinforcement ratios to distribute cracks finely.

- Limiting bar spacing to control crack width.

- Use of crack width calculations as per standards like ACI 318 or Eurocode 2.

Examples in Structural Elements

Beams

Beams are typically designed assuming cracked sections in tension zones. The bottom fibers are prone to cracking under positive bending moments, transferring tensile stress to the reinforcement.

Slabs

In one-way and two-way slabs, cracking occurs primarily in the tension face (bottom for simply supported slabs). Adequate distribution reinforcement is required to control cracks.

Columns

Columns often remain uncracked because they are primarily axially loaded in compression. However, in slender columns or eccentric loading cases, cracking might occur on tension sides.

Foundations and Retaining Walls

These elements may experience temperature and shrinkage cracks even if loads are low. Design typically includes temperature reinforcement and expansion joints to control these effects.

Importance in Structural Analysis and Modeling

Accurate modeling of concrete behavior requires acknowledging whether a section is cracked or uncracked:

- Linear-elastic analysis assumes uncracked sections.

- Nonlinear or cracked section analysis involves reduced stiffness properties and incorporates tension stiffening effects.

Software tools like ETABS, SAP2000, and STAAD.Pro allow users to define material behavior based on cracking assumptions to simulate real-world performance more precisely.

Durability and Long-Term Performance

Cracked sections are more vulnerable to environmental attack, especially in aggressive conditions involving chlorides, sulfates, or carbonation. To enhance durability:

- Use of high-performance concrete (HPC).

- Application of protective coatings and sealants.

- Cathodic protection systems in critical infrastructures.

Conclusion

The distinction between cracked and uncracked concrete sections forms a cornerstone in the design, analysis, and maintenance of concrete structures. Understanding these states allows engineers to predict performance, ensure safety, control deflection, and prolong the service life of reinforced concrete members.

Proper design to either prevent cracking or manage its consequences ensures structures remain functional, safe, and durable throughout their intended lifespan.

Please view the following short video for Cracked and Uncracked Concrete Section