Overview of Prestressed Concrete

Concrete has significant strength, but its bending strength is very limited. Thus, designers use reinforcement in conjunction with concrete to make useful substances in buildings. Researchers have found out that bending stresses could be eliminated in concrete buildings by adding sufficient compressive stresses to balance them out. Then the element would have a stress distribution throughout that consisted of compression only.

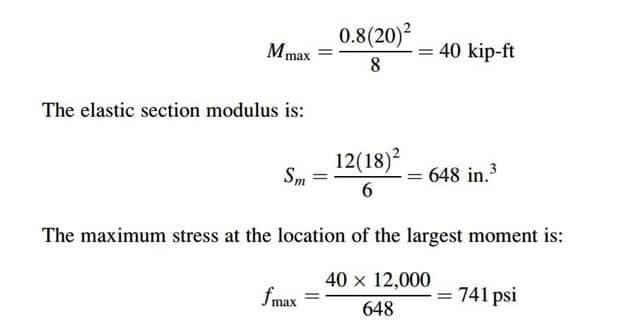

Below sum shows a simply-supported beam with an applied distributed load w 1/4 800 lb/ft. The cross section of the beam is b 1/4 12 in. and h 1/4 18 in. If this beam is made of a similar elastic material, the stresses can be calculated as follows:

This value represents the constant pressure at the top edge of the section, and a similar magnitude of pressure at the bottom edge. Based on the discussions on the compassion strength of concrete , we end it that a plain (unreinforced) concrete beam would fail under this load.

Advantages of Prestressed Concrete Structures

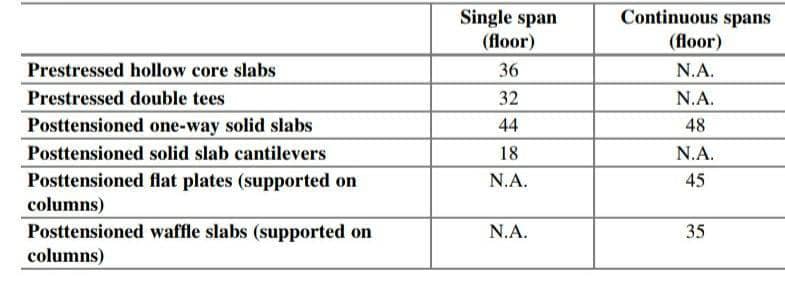

One major advantage of prestressing is that it prevents cracks in the concrete structure by either limiting or completely eliminating tensile stresses in the structure. But prestressing has another very important advantage. Prestressed structural elements can be much deeper than normal reinforced concrete elements for the same span and loading conditions, while still maintaining good deflection ratios.

The savings extend to reduced floor-to-floor heights and lighter column and foundation loads as well. The reduced floor-to-floor height in multi-storey buildings results in large savings in non-structural building elements such as walls. The reduced building volume also decreases the energy needed for heating and cooling.

Types of Prestressing

Pretensioning

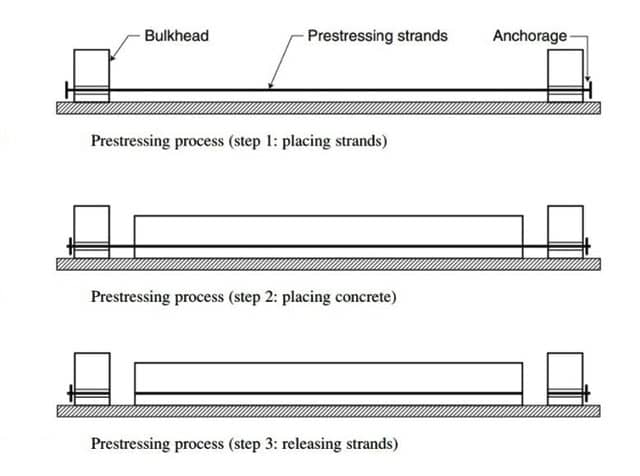

In pretensioning, as the expression illustrates, the prestressing strands are tensioned before the casting of the element by stretching and fixing them against two bulkheads, as illustrated in Figure 9.6. The bulkheads are very strong and designed to take the large forces from the initial stretching of the prestressing strands. The strands are anchored at one end (the "dead" end) and then pulled from the other end (the "live" end) one by one with a specially designed hydraulic jack.

The force in the strands can be measured directly on the jack or determined from the amount of elongation. Elongation is directly related to the stress in the strand, so we can readily determine the force in the strand if we know the cross-sectional area of the strand. The strands are anchored at the live edge as well as once the appropriate force has been reached.

Posttensioning

Posttensioning is a technique used to prestress concrete structures on the job site after the concrete has been cast into the forms and cured. It contrasts from pretensioning, which is generally use to manufacture building elements aside from the building site. The posttensioning technique places flexible hollow metal or plastic tubes into the formwork to form ducts.

Tendons are inserted through the ducts after the concrete has cured. Other techniques place plastic sheeted tendons into the formwork. The plastic sheet prevents the tendons from bonding with the cast concrete. The strand or tendon is anchored at one end to a device or plate cast into the concrete (the "dead" end). Portable hydraulic jacks from the "live" end provide tensioning.