Concrete Slump Test Procedures and Types

The concrete slump test is used during construction to determine the quality of concrete mixes prepared in the lab or on-site. Concrete slump tests are performed during construction to check for uniformity in concrete quality. Concrete slump testing is the simplest, cheapest, and fastest method of determining its workability.

Concrete Workability

When describing concrete's workability, you are describing its ability to be mixed, transported, and placed uniformly. Mixes are workable depending on their water content, aggregate quality, and fine material content. Several researchers have tried measuring the workability of concrete using different parameters, and they have discovered some tests that are very close to checking it.

Concrete Slump Value

Workability is generally determined by the concrete slump value, which indicates the water-cement ratio, though other factors such as material properties, mixing methods, dosage, admixtures, etc. can also influence the concrete slump value.

Slump Test

However, it is not suitable for extremely wet or extremely dry concrete despite how easy this method is to use. Slump tests help determine concrete uniformity from batch to batch, and this test can be used for that purpose. Similarly, repeat batches of the same mix will have the same amount of water & water-cement ratio, the weights of aggregate, cement, and additives will be uniform. The aggregate grade will be within acceptable limits.

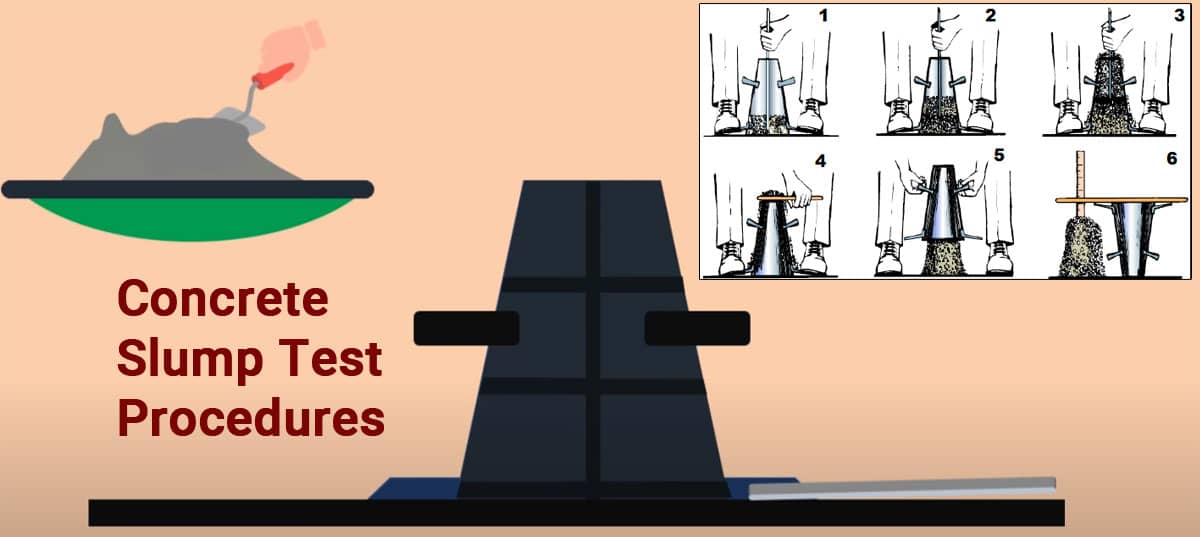

The Procedure of Slump Test

- You should clean the mold's interior and apply oil to it.

- Placing the mold on a smooth, non-porous horizontal base will ensure a stable product.

- Four layers of approximately equal concrete mix are poured into the mold.

- Over the cross-section of the mold, tamp each layer with 25 strokes using the rounded end of the tamping rod. Tamping should penetrate the underlying layers for the subsequent layers.

- Level the surface with a trowel after removing the excess concrete.

- Dispose of all mortar or water that leaked between the base plate and the mold.

- After removing the mold from the concrete, raise it vertically.

- Calculate the slump by comparing the mold height to the height point of the specimen being tested.

Slump Test Result

Take an mm measurement of both the height of the mold and the highest point of the slump. The Slump value is determined by the height difference between the mold and the highest point of subsiding.

Types of Slump in Concrete

Zero Slump

A concrete mix with zero slumps indicates a very low water-to-cement ratio, resulting in a dry mix. Most road construction uses concrete of this type.

True Slump

There is only one type of slump that can be measured by the test, the true slump. Once the cone has been removed, the top of the concrete is measured from the cone's top to the concrete's top.

Shear Slump

The slump is called a Shear Slump if half of it slides down. Clearly, the concrete does not adhere together and displays characteristics of segregation. The concrete was found to have a shear slump during the test, indicating that retesting is necessary.

Collapse Slump

Slump tests are not appropriate for high workability mixes or mixes with a high water-cement ratio. In a collapse slump, the entire slump is disintegrated in all directions without resembling a mold shape at all. A large amount of water is added to the concrete mix to increase its workability.

Please follow the followingTutorials