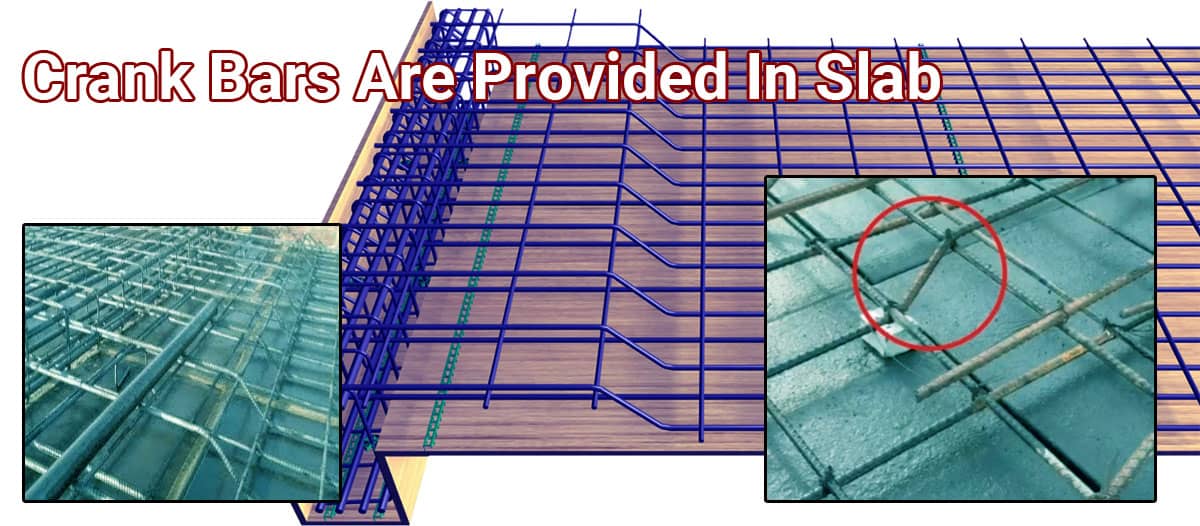

Crank Bars are Provided In Slab and Why ?

Crank bar, also referred to as bent up bar is extremely important for slabs. it's also important for preparing a bar bending schedule.

What is Crank Bar?

Different shape of cranks bar is provided within the slab and other structural members. Bars are bent near the supports normally at an angle of 45°. The angle bent can also be 30° in shallow beams where the (effective depth < 1.5 breadth).

The maximum tensile stress that's positive moments (sagging) acting within the middle of the slab and therefore the maximum compressive stress that's negative moments (hogging) working at both ends of the support.

So bottom steel is required at the mid-span and top steel resists negative moments at the supports. A crank bar is provided to form RCC slab safe from compressive stresses.

When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased.

Purpose of Crank Bar:

Crank bars are generally provided

- To resist negative bending moment (hogging).

- To resist shear force which is bigger at supports.

- To scale back the danger of a brittle failure of slab-column connection.

- To scale back the quantity of steel used.

- For the economization of materials.