Importance of Building Site Layouts

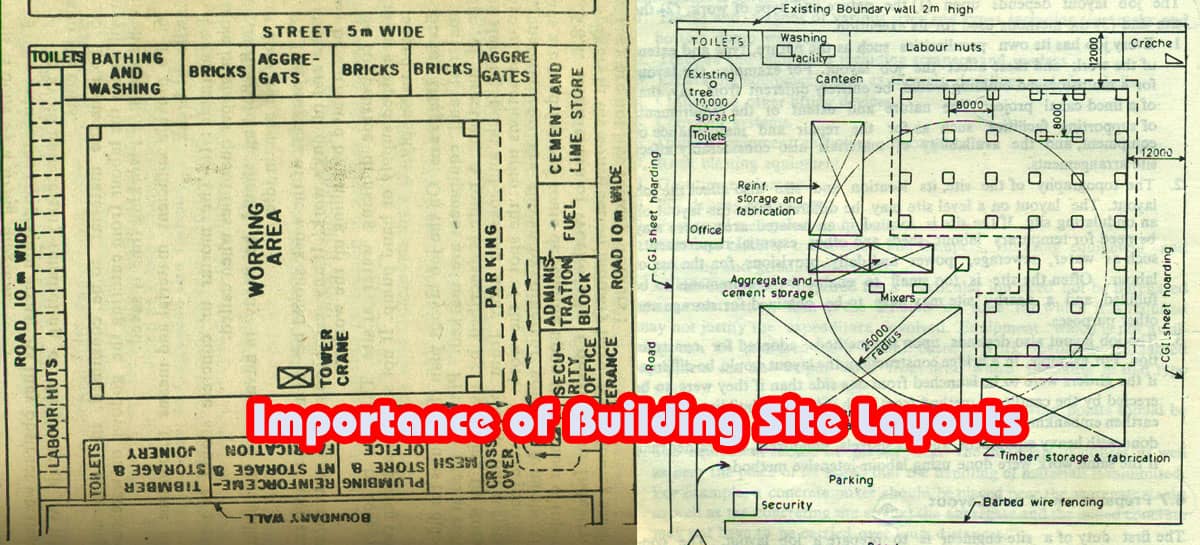

Site Layouts, or Job Layouts, are the overall symbolistic plan of the building areas. A Site Layout shows the area of construction and landscaping (if any) and pinpoints the locations of resources to be placed throughout the sites.

A Job Layout will also depict the place and area of various facilities at the job site such as the offices, godowns, workshops, accommodations, etc. Not only that, but a site plan will also clarify the relationship of a building site with its surroundings in terms of ingresses and egresses, impact on and off existing construction, and environmental effects.

Why do we need a Site Layout?

A proficiently made error-free systematic site layout is the starting point of most large construction projects, for the following reasons:

- A properly planned site layout will give you a sufficient amount of resources with a continuous supply.

- The site layout will let you have clear access to your materials.

- You will be able to understand the wastages of materials and calculate losses due to deterioration.

- Through intuitive planning, you can reduce the need for plants and heavy equipment on site.

- A clear, well-structured site plan reduces accidents due to confusion at the building site.

- A tidied up layout will provide invaluable assistance to materials inspection and auditing.

An optimum site layout is the one site layout which fulfills all or most of the conditions described above. Such a job layout will increase efficiency at the building site by smoothing the workflow.

Factors affecting the Site Layout

There are multiple factors that can dramatically alter or skew the characteristics of a site layout. These are:

- Location of Site: the building site location, whether urban, rural, natural, etc.

- Site Space: the space that is available in and around the construction site.

- Material mass: the bulk size of all the materials that are necessary to be kept on-site at one time.

- Equipment type: the nature and volume of the equipment to be used in construction. Power and energy also come in this.

- Ground conditions: the nature of the ground at the construction site will severely affect the site plan.

Site Layout Principles:

To promote efficiency, tidiness, economy, and safety at the construction site, the following principles or guidelines should be adhered to while making the job layout.

- Two openings: The job site should have more than one opening for a better flow of control of foot and vehicle traffic within the workspace. Ideally, an Entry point and an Exit point far apart serve best.

- General Office: since the General office attracts the most foot traffic and most decisions are made from there, it should be placed as close to the main gate as possible. This will help reduce confusion at the job site.

- Godown: for better delivery and fetching of materials, and also for closer store supervision, the main godown should be placed right behind the main office.

- Temporary roads: ad-hoc roads, streets and accessways should be planfully constructed around the building site for proper flow of traffic and movement of the equipment. These roads are often constructed first at the building site and then the building is erected utilizing their logistical support.

- Supporting Workshops: The locations of the workshops to be used by joiners, electricians, fitters, etc. should be decided based on ease of access and a short distance from their affected points. These may keep changing throughout a long construction project.

- Accommodation: The living, dining, and relaxation space for staff who have to stay on-site should be located as far from the main source of noise and pollution in the building site as possible.

- Recycle services: for optimum economy and efficiency, don't hesitate to use up the existing services and structures to the limit of their abilities.