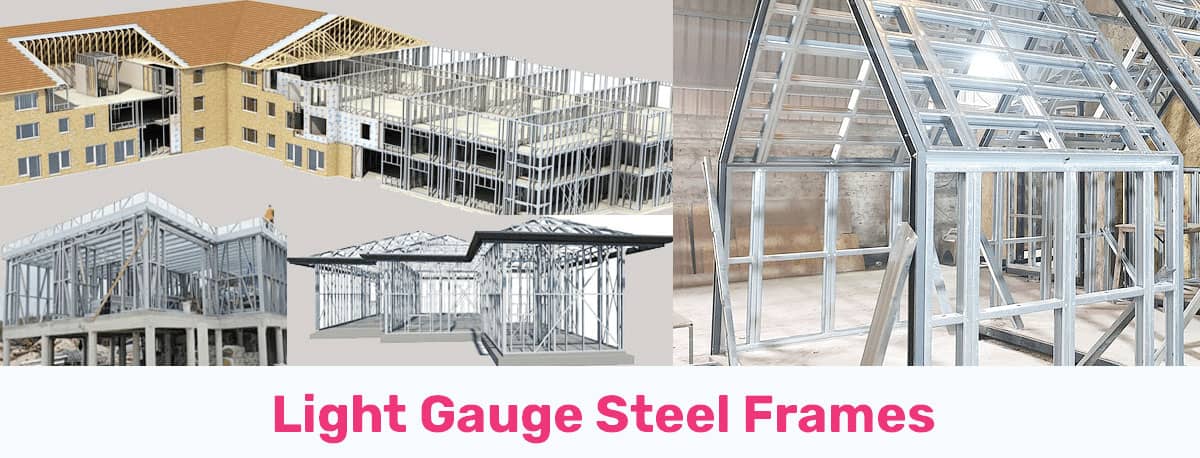

Light Gauge Steel Frames in Construction

There is a new construction method on the market, and it is quite cool. Called the Light Gauge Steel Frame Construction, it is successfully replacing the standard wood frame construction method. This innovative method is being widely accepted in many building designs and construction aspects.

The Light Gauge Steel Frames offer several advantages. Some of them are design flexibility, strength, sustainability, buildability, etc. This makes Light Gauge Steel Frames easier to build and much safer too. Not only that, it is also faster to build. Word to the wise, though - the light steel frame is susceptible to fire, so fire protection coating needs to be provided.

Based on ASTM standard A1003, Light Gauge Steel Frames are manufactured from structural steel sheets. These sheets are formed into 'C' 'Z' and 'S' shapes. This makes the structure strong and able to support heavy loads. It is also called cold formed steel. This is because of the process by which it is manufactured.

This added strength and flexibility leads Light Gauge Steel Frames to support increased spans. They can be shaped into custom openings. Moreover, they can support many different types of external facade treatments. This sheer versatility is making the Light Gauge Steel Frames very popular among modern constructors.

One thing to be noted about Light Gauge Steel Frames is they are much more susceptible to corrosion effects than standard wooden frames. For this reason, they have to be provided with zinc, aluminum or combo coatings to make them corrosion-resistant over long periods.

Light Gauge Steel Frame Components:

Wall System: This is a load bearing wall that supports vertical load or lateral loads.

Flooring System: The floor sections can be made from C-section joists connected to bearers.

Roof System: The roof structure is composed generally from steel trusses for metal sheets or tiles.

Light Gauge Steel Coating: Environmental conditions dictate how thick the corrosion-resistant coating should be.

Shapes of Steel frame Members: Studs, joints and rafters are made with C-shaped webs, which are manufactured with holes at 600mm intervals.

Accessories: Various sheet metal angles, straps, plates, channels, and miscellaneous shapes come together to hold up the whole structure.

Connections: These are connected commonly with self-tapping self-drilling screws. The members can also be welded together if need be.

Thickness of base plate: Minimum thickness of the base sheet metal for Light Gauge Steel Frame elements needs to be maintained strictly accordingly to the following table:

| Gauge | Minimum Thickness of Steel Sheet | Minimum Thickness of Steel Sheet |

| - | Load bearing Light Gauge Steel Framing, mm | Nonload bearing Light Gauge Steel Framing, mm |

| 12 | 2.43 | - |

| 14 | 1.73 | - |

| 16 | 1.37 | 1.37 |

| 18 | 1.09 | 1.09 |

| 20 | 0.84 | 0.75 |

| 22 | - | 0.69 |

| 25 | - | 0.45 |

Advantages of Light Gauge Steel Frames: Buildability, Lightweight, Strength, Design Flexibility, Speed of Construction, Structural Safety, Quality, Easy remodeling, Recyclability.

Cons of using Light Gauge Steel Frames - You might need to reconsider using Light Gauge Steel Frames in construction for the following reasons:

- The steel does not catch fire but the lightness of it makes it vulnerable to fire nonetheless.

- Light frames structures let sound to pass through walls. This can be highly undesirable, especially in compact urban settings.