Brief note on Singly Beam and Doubly Beam

Singly Beam

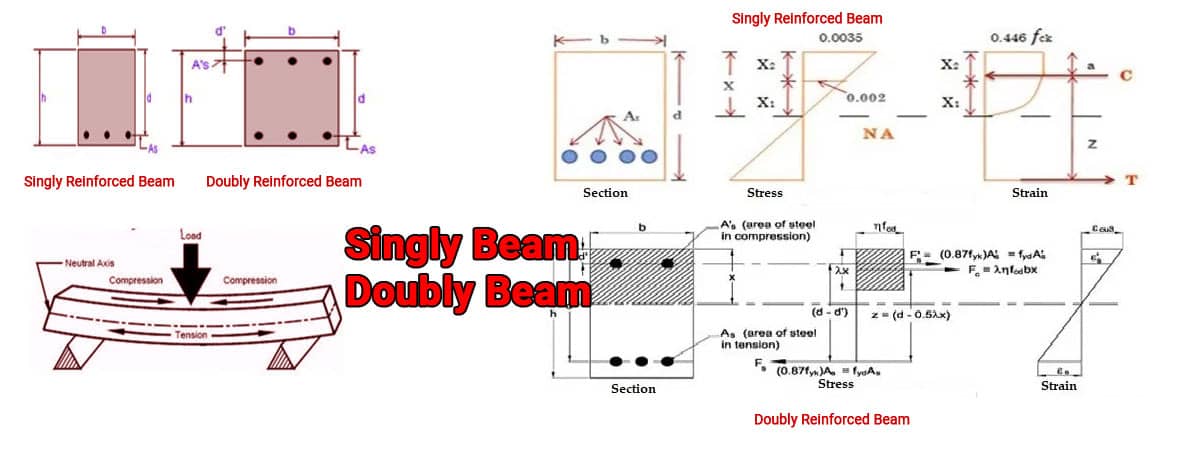

A singly beam is that the beam which is given longitudinal reinforcement within the tension zone. Compressive forces are handled by the concrete section within the beam.

Doubly Beam

The beams reinforced with steel in compression and tension zones are referred to as doubly reinforced beams. this type of beam are going to be found essential when headroom consideration or architectural concern the depth of the beam is restricted.

The beam with its restricted depth, if reinforced provided on the strain side only, it's going to not have sufficient moment of resistance to resist the bending moment.

By raising the number of steel within the tension zone, the instant of resistance can't be increased indefinitely. Generally, the instant of resistance are often increased by less than 25% beyond the balance moment of resistance by making the beam reinforced on the strain face.

Hence, to additional increase, the instant of resistance of a beam section of unlimited dimensions, a doubly reinforced beam is provided.

Singly Reinforced Beam

Reinforcements are provided to oppose tensile stresses thanks to shear and bending in beams for singly reinforced beam sections. Practically, for singly reinforced beams, two additional bars are supplied within the compression face of the beam in order that stirrups are often tied with bars easily. These extra reinforcements are of the nominal diameter of 8mm or 10mm.

Doubly Reinforced Beam

When the depth of the section is restricted thanks to reasons like, like architectural reasons or basement floors, the beam section is meant as a doubly ferroconcrete beam.

These bars shall withstand in compressive stresses and are given reinforcement in compression face.

Beams, when subjected to in torsion, are provided additional longitudinal and shear reinforcement to resist bending, and shear stresses developed thanks to torsion.

Besides this, doubly reinforced beams are often utilized under following conditions,

- When the surface load is alternating, meaning the load is working on the face of the member.

- The load is eccentric and therefore the eccentricity of the load is changing from one side to a different side of the axis.

- The member is subjected to a shock or impact or accidental lateral thrust.