Types of Scaffolding in Building Construction

Scaffolding is a temporary rigid structure having still, bamboo, or timber platforms raised up with accelerating the edifice height. It enables the mason to work at different stages of a edifice and takes up the accoutrements for immediate use at chromatic heights. Different types of scaffolding are used depending upon the types of construction.

Useful Terms Related To scaffolding

- Standard It's a raised member supported on the ground.

- Receipts Receipts are the longitudinal flush members connected with morality.

- Braces Braces are the oblique members that are connected with morality to harshen the structure.

- Put Logs Put logs are the transverse even members that are 90 cm in length and are generally spaced 120 cm apart. They're gave to support the working platform.

- Transoms When both the ends of putlogs are connected with expenses, it's called transoms.

- Boarding Boarding is a erect member supported by putlogs. It's used to enable the mason and stuff.

- Guard Rail It's ditto to charges, used for better protection at the working reach.

- Toe Board It's a long plane board of wood used at different working reaches.

Types of Scaffolding

Different types of scaffolding are described below

Brick estate's scaffolding

This type of scaffolding consists of ethos forcibly secured on the grounds at2.4 to 3 m. The ethos are connected to each other by invoices at every rise of 120 to 150 cm. They're fed on the edifice locality of the ethos and are secured in position by rope-lashing.

Putlogs are lashed on the reckonings at one end and into the holes in the wall at the other end. In high scaffolding, cross braces are continually used to strengthen the temporary structure. Braces correspond of poles tied by rope-lashing on the morals.

Mason's scaffolding

Since it's touchy to leave holes in the tombstone masonry to hand a bearing for the putlogs, in mason's scaffolding two frames of norms, at a distance of1.5 m from the first one. So the mason's scaffolding is entirely independent of the tombstone wall.

Close mason's scaffolding They're supposed to carry loads of heavy blocks of tombstones and the stresses produced on account of the lifting device and hence they're made stronger by placing the norms at a fairly close distance apart.

Blade or tubular scaffolding,

The construction of brand scaffolding is correspondent to that of timber scaffolding. In this case, the inelegant members are replaced by 38 mm to 64 mm periphery brand tubes and instead of rope-lashings, special types of brand duos or fittings are used for connecting different members.

The brand tubes used for scaffolding for normal structure construction work are heavy class and of circuit varying from 40 to 60 mm.

In this type of scaffolding, the standing tubes called uprights or morals are spaced2.5 to 3 m apart. Each standard is welded to a base plate, square or indirect in plan. The base plate has holes so that it can be spiked to a timber or concrete base, so forming a rigid foundation for the scaffolding.

Tolls or the longitudinal tubes connecting the standard and are spaced at1.8 m vertically apart. Short tubes or put logs are ordinarily1.2 m to1.8 m in length. The putlogs have special ends to fit into the joints in the wall and so no big holes are wanted to be left on the wall for their bearing.

Tubular scaffolding has several advantages over timber scaffolding similar as swift structure and dismantling, mean strength and persistence, progressive fire withstanding rates, and salvage value.

Although it works out to be high-ticket initially, but considering its several advantages and the increased number of plays, it proves to be provident in the long run and hence it's being considerably used these days.

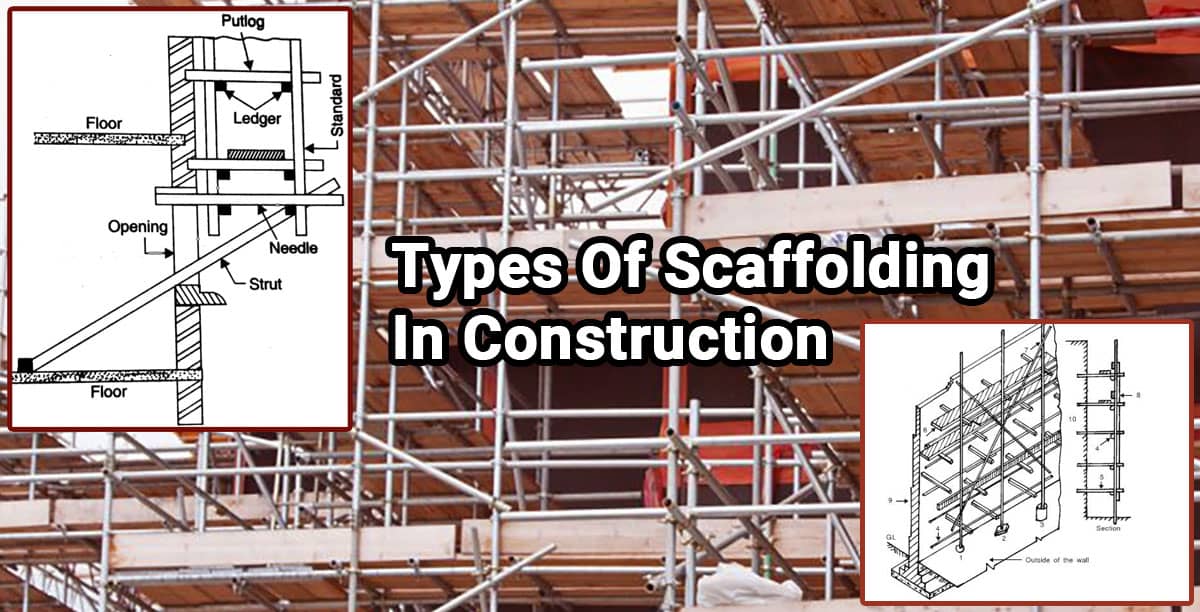

Needle scaffolding.

When scaffolding is to feed for a edifice on the side of a busy drive where the construction of ordinary scaffolding will obstruct the commerce on road, a needle rostrum is used.

The dais is erected from window corners of string courses by means of projecting needles. A needle is a timber ray that cantilevers out through the holes cut in the wall.

From inside the needles are supported on sole pieces and are averted from lifting up by erect struts crammed between the needles and the caps. The projected end of the needle is supported by an inclined strut that rests on the window brace.

The joint between the trolling or inclined strut and the needle is clamped by means of pooches. The arrangement provides the staging for the structure of ordinary types of scaffolding.