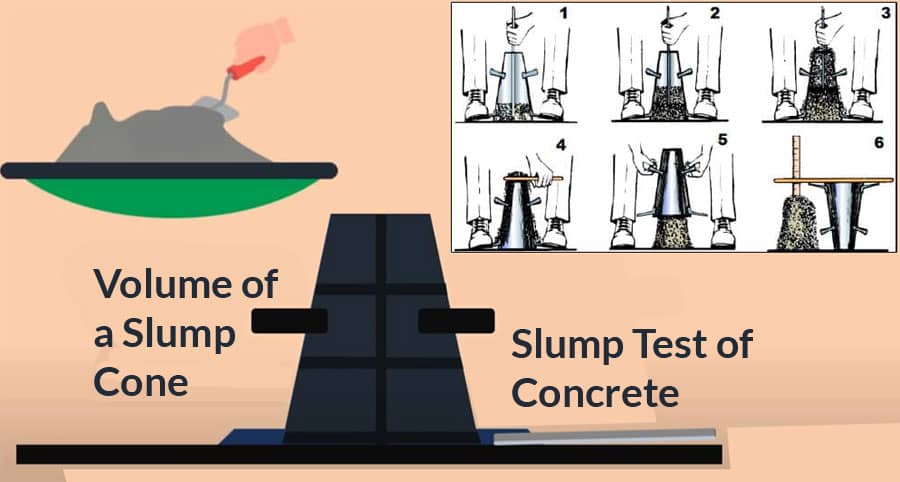

How to Find Volume of a Slump Cone | Slump Test of Concrete

The slump test is one of the most critical and widely used methods in the field of concrete construction to determine the workability of concrete mix. The procedure not only helps us gauge the quality of the concrete but also provides essential data on the consistency and uniformity of the mix. Central to the slump test is the slump cone, a specific apparatus used to measure the deformation and shape change in a fresh batch of concrete.

Understanding how to calculate the volume of the slump cone is equally essential for accurate testing and analysis. In this comprehensive guide, we will walk you through the essential aspects of the slump test and show you how to determine the slump cone's volume for precise measurement.

What is the Slump Test of Concrete?

The slump test is primarily used to measure the workability or fluidity of a fresh concrete mix. Workability refers to how easily the concrete can be mixed, transported, and placed without segregation. The test is performed by placing fresh concrete into a conical metal mold known as the slump cone, and then removing the mold to observe the vertical settlement or "slump" of the concrete.

The slump test is a quick, cost-effective, and efficient way to check the consistency of concrete. It helps in detecting variations in water content, aggregate quality, and other factors that could affect the performance of the concrete.

Dimensions of the Slump Cone

Before diving into the calculations, it's essential to understand the physical dimensions of the slump cone used in the test:

- Top Diameter (D1): 100 mm (10 cm)

- Bottom Diameter (D2): 200 mm (20 cm)

- Height (h): 300 mm (30 cm)

These standard dimensions are used worldwide for conducting the slump test in accordance with established guidelines such as ASTM C143 and EN 12350-2.

Formula for Calculating the Volume of a Slump Cone

The slump cone has a truncated conical shape, which means it has two different circular cross-sections at the top and bottom. The formula used to calculate the volume of a truncated cone is:

V = 1/3 πh ( r21 + r1r2 + r22 )

Where:

- V = Volume of the slump cone

- π = Pi (3.14159)

- h = Height of the cone (300 mm)

- r1 = Radius of the top of the cone (50 mm)

- r2 = Radius of the base of the cone (100 mm)

Step-by-Step Calculation

- Convert Diameters to Radii:

- Top Radius (r1) = 100 mm ÷ 2 = 50 mm

- Bottom Radius (r2) = 200 mm ÷ 2 = 100 mm

- Plug Values into the Formula: Using the formula mentioned above, let's calculate the volume of the slump cone.

V = 1/3 X 3.14159 X 300 ( 502 + 50 X 100 + 1002 ) - Simplify:

V = 1/3 X 3.14159 X 300 ( 2500 + 5000 + 10000 )

V = 1/3 X 3.14159 X 300 X 17500 - Final Volume Calculation:

V = 1/3 X 3.14159 X 300 X 5833.33V = 5497785.8 mm3

Now, convert the result into liters (since 1 liter = 1,000,000 mm3):

V = 5.498 liters

Thus, the volume of the slump cone is approximately 5.5 liters.

Why Knowing the Volume is Important?

Knowing the volume of the slump cone is essential for several reasons:

- Accurate Measurements: In laboratory settings, understanding the exact volume allows for a more precise estimation of the slump in the concrete. This is crucial for controlling the workability and water-cement ratio of the concrete mix.

- Standardized Testing: The volume must be consistent across tests to ensure that results are comparable. This consistency allows engineers and site managers to ensure that the concrete meets the required specifications for strength, durability, and placement.

- Quality Control: By knowing the volume, it's easier to detect variations in mix proportions, which might affect the strength and longevity of the concrete structure. For example, if the slump is too high, the concrete could be overly fluid, leading to segregation or improper curing. On the other hand, if the slump is too low, the mix may be too stiff, leading to issues during placement.

Performing the Slump Test: Step-by-Step Procedure

Performing the slump test is straightforward, but each step must be carried out with precision to obtain accurate results. Here's how to conduct the test:

Step 1: Preparation

- Ensure that the slump cone is clean, free of debris, and properly lubricated.

- Place the cone on a flat, non-absorbent base plate.

- Keep a rod handy for compacting the concrete.

Step 2: Filling the Cone

- Fill the cone with fresh concrete in three layers.

- Each layer should occupy approximately one-third of the cone's height.

- After adding each layer, compact it with 25 strokes of the tamping rod to remove air pockets and ensure uniformity.

Step 3: Remove the Cone

- Once the cone is filled and leveled, carefully lift the cone vertically without tilting.

- The concrete will "slump" or settle downward due to gravity.

Step 4: Measure the Slump

- Measure the vertical displacement of the top surface of the slumped concrete from the original height of the cone.

- The measured slump indicates the workability of the concrete. The higher the slump, the more fluid the concrete.

Interpretation of Slump Test Results

- True Slump: If the concrete retains its shape and only settles vertically, this is called a true slump and indicates a balanced mix.

- Shear Slump: If part of the concrete shears off and slides down, this indicates a lack of cohesion in the mix.

- Collapse Slump: If the concrete collapses completely, it is too wet and likely has too much water.

Each type of slump gives a clue about the quality and consistency of the concrete mix, which is vital for ensuring structural integrity.

Conclusion

Understanding how to find the volume of a slump cone and performing the slump test correctly are critical steps in assessing the workability of fresh concrete. The formula for determining the volume of a truncated cone is straightforward, and the procedure for conducting the test is an essential part of quality control in any concrete project. Whether you're involved in residential construction or large-scale infrastructure, mastering the slump test helps ensure that your concrete meets the required standards for strength, durability, and performance.

For more information, please watch video tutorial