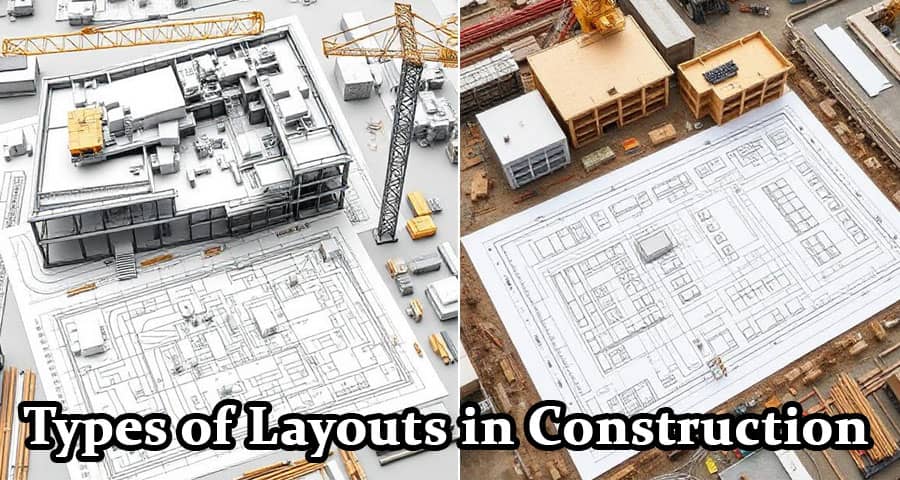

What are the Types of Layouts in Construction?

In the field of construction, accurate layout planning is the bedrock of a successful project. The layout sets the blueprint for where every component of a building or structure will be placed. It not only ensures spatial accuracy but also enhances the efficiency of labor, material usage, and machinery deployment.

1. Building Layout

Building layout is the most common type used in residential, commercial, and industrial construction. This involves marking the position of walls, columns, and other structural components on the ground.

Key Characteristics:

- Conducted using total stations, theodolites, or leveling instruments.

- Based on architectural and structural drawings.

- Foundation pits are excavated as per the marked lines.

Applications:

- Residential buildings

- Office complexes

- Industrial warehouses

2. Site Layout

A site layout includes the arrangement of temporary facilities such as site offices, material storage, worker housing, and sanitation units on the construction site.

Key Characteristics:

- Ensures smooth logistics and reduces idle time.

- Involves zoning for safety, efficiency, and regulatory compliance.

- Requires periodic updates during different project phases.

Applications:

- Large infrastructure projects

- Construction of factories and plants

- Multi-phased construction operations

3. Foundation Layout

The foundation layout focuses specifically on marking the exact points where foundations, including isolated footings or strip footings, are to be constructed.

Key Characteristics:

- Involves precise trench marking.

- Requires high accuracy to avoid misalignment.

- Conducted after soil compaction and geotechnical assessments.

Applications:

- High-rise buildings

- Bridges

- Commercial structures

4. Column Layout

Column layout involves plotting the positions of columns on the ground or slab using coordinates taken from structural drawings.

Key Characteristics:

- Coordinates are cross-verified using gridlines.

- Essential for multistory construction to ensure vertical alignment.

- Commonly marked using chalk, ink, or pegs.

Applications:

- Office towers

- Shopping malls

- Hospitals and educational institutions

5. Grid Layout

A grid layout refers to the method of dividing the entire construction site into an organized grid, enabling efficient placement and alignment of structural elements.

Key Characteristics:

- Follows a systematic x-y coordinate system.

- Used in conjunction with total stations and CAD drawings.

- Simplifies large-scale site management.

Applications:

- Airports

- Stadiums

- Urban planning projects

6. Road Layout

Road layout in construction is applied when marking the centerline, curves, and widths of roads, pavements, and highways.

Key Characteristics:

- Uses road centerline drawings and contour maps.

- Requires advanced instruments for slope calculation.

- Involves longitudinal and cross-sectional layout.

Applications:

- Highway development

- Driveway installation

- Urban and rural road planning

7. Pipeline Layout

Pipeline layout involves the placement and routing of pipelines for water, sewage, gas, or oil.

Key Characteristics:

- Accounts for pressure zones, flow rates, and elevation changes.

- Layouts follow utility plans and require depth checks.

- Coordinates must be highly accurate to prevent leaks or breaks.

Applications:

- Municipal infrastructure

- Industrial utility networks

- Water treatment facilities

8. Electrical Layout

An electrical layout maps out the routes and positions of electrical conduits, junction boxes, wiring systems, and switchboards.

Key Characteristics:

- Reflects the power requirements and lighting plan.

- Coordination with structural and architectural layouts is essential.

- Includes main distribution panels and emergency power lines.

Applications:

- Smart buildings

- Manufacturing plants

- Data centers

9. HVAC and Mechanical Layout

HVAC (Heating, Ventilation, and Air Conditioning) and mechanical layouts deal with ducting, chillers, ventilation shafts, and mechanical equipment placement.

Key Characteristics:

- Focuses on thermal comfort and indoor air quality.

- Requires integration with false ceilings and utility shafts.

- Includes placement for exhaust systems and fire safety vents.

Applications:

- Commercial towers

- Cinemas and auditoriums

- Server rooms and laboratories

10. Plumbing Layout

Plumbing layout guides the installation of water supply lines, drainage systems, and sanitation fixtures.

Key Characteristics:

- Ensures minimal pipe interference with other services.

- Complies with local plumbing codes and water pressure requirements.

- Integrated during the slab and wall stage of construction.

Applications:

- Residential buildings

- Public restrooms

- Restaurants and hotels

11. Landscaping Layout

This layout involves the arrangement of gardens, lawns, water bodies, and recreational zones surrounding the built structure.

Key Characteristics:

- Incorporates topography and drainage patterns.

- Designed for aesthetics and environmental sustainability.

- Includes irrigation systems and paving layouts.

Applications:

- Resorts and villas

- Parks and recreational zones

- Green building projects

12. Structural Layout

The structural layout includes all load-bearing elements of the building: beams, slabs, trusses, and load-transferring systems.

Key Characteristics:

- Relies on load calculations and material specs.

- Helps in determining reinforcement and stress zones.

- Directly influences the safety and longevity of the building.

Applications:

- Bridges and flyovers

- Multi-level car parks

- Heavy-duty manufacturing units

13. Interior Layout

The interior layout specifies the positioning of partitions, furniture, fixtures, and decor within the completed structure.

Key Characteristics:

- Involves space optimization and functional zoning.

- Harmonizes lighting, electricals, and plumbing.

- Reflects client preferences and ergonomics.

Applications:

- Office interiors

- Luxury residences

- Retail stores

14. Modular Layout

Modular layout pertains to pre-fabricated construction techniques where modules are manufactured off-site and assembled on location.

Key Characteristics:

- Reduces construction time drastically.

- Layouts must support transport and installation logistics.

- Offers sustainability and cost-effectiveness.

Applications:

- Temporary housing

- Schools and hospitals

- Military installations

Conclusion

Understanding the diverse types of layouts in construction is vital for precise planning, optimal resource allocation, and timely execution. Each layout type is tailored to fulfill specific functional and structural requirements, contributing directly to the project's success. Incorporating the correct layout strategy ensures that the construction process remains seamless, compliant, and aligned with the design vision.

Please view the following short video for Types of Layouts in Construction