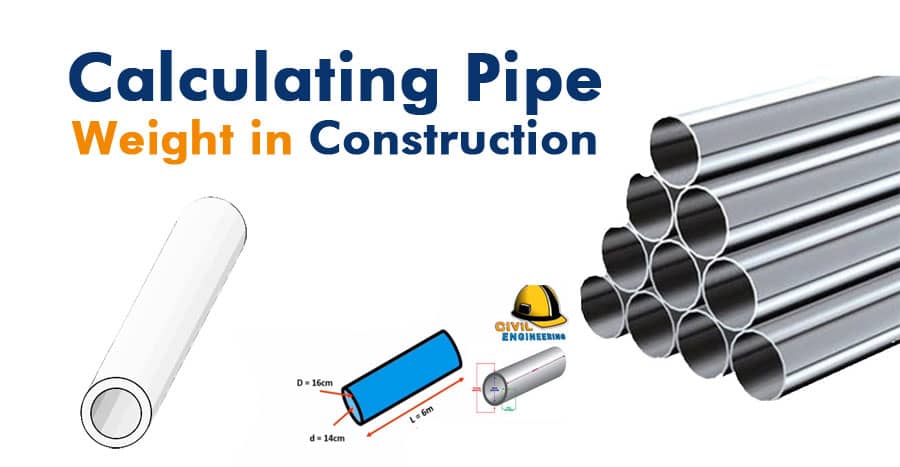

Calculating Pipe Weight in Construction

Pipe Weight Calculation

In construction projects involving piping systems, accurately estimating the weight of pipes is crucial for structural integrity, material selection, transportation, and installation planning. Whether it's for plumbing, irrigation, or industrial applications, understanding how to calculate pipe weight is essential for ensuring the success of the project.

Factors Affecting Pipe Weight

Before delving into the calculation process, it's essential to consider the factors that influence the weight of a pipe:

- Material Type: Pipes can be made from various materials, including steel, copper, PVC (polyvinyl chloride), HDPE (high-density polyethylene), and others. Each material has a different density and weight per unit volume.

- Pipe Dimensions: The size and dimensions of the pipe significantly impact its weight. This includes the diameter (outer and inner), wall thickness, and length of the pipe.

- Wall Thickness: Thicker walls result in heavier pipes due to the increased volume of material used.

- Pipe Schedule (for Steel Pipes): Steel pipes are often classified based on their wall thickness and pressure capacity, known as pipe schedules. Higher schedule numbers indicate thicker walls and, consequently, heavier pipes.

Calculation Methods for Pipe Weight

Formula for Steel Pipes

For steel pipes, the calculation of weight is relatively straightforward and involves the following formula:

Weight = ( Outer Diameter - Inner Diameter ) x Wall Thickness x Length x Density

Where:

- Outer Diameter: The external diameter of the pipe.

- Inner Diameter: The internal diameter of the pipe.

- Wall Thickness: The thickness of the pipe wall.

- Length: The length of the pipe.

- Density: The density of the steel material (usually expressed in pounds per cubic inch or kilograms per cubic meter).

Formula for Non-Steel Pipes

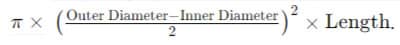

For pipes made from materials other than steel, such as PVC or HDPE, the calculation method may differ based on the material properties. Generally, the weight can be calculated using the following formula:

Weight = Volume x Density

Where:

- Volume: The volume of the pipe, calculated based on its dimensions (outer diameter, wall thickness, and length).

- Density: The density of the pipe material.

Practical Steps for Pipe Weight Calculation

- Gather Pipe Specifications: Collect the necessary information about the pipe, including its material type, dimensions (outer diameter, wall thickness), and length.

- Determine Material Density: Refer to material specifications or engineering references to find the density of the pipe material. This value is typically provided in weight per unit volume (e.g., pounds per cubic inch or kilograms per cubic meter).

- Calculate Pipe Volume: For non-steel pipes, calculate the volume using appropriate geometric formulas based on the pipe's shape (e.g., cylindrical for most pipes). For steel pipes, use the formula

- Apply the Weight Calculation Formula: Using the calculated volume (or dimensions) and the material density, apply the appropriate weight calculation formula to determine the total weight of the pipe.

Conclusion

Accurately calculating the weight of pipes is essential for various aspects of construction projects, from material selection to structural design and logistics planning. By understanding the factors influencing pipe weight and employing the appropriate calculation methods, construction professionals can ensure the successful execution of piping systems with optimal efficiency and safety.