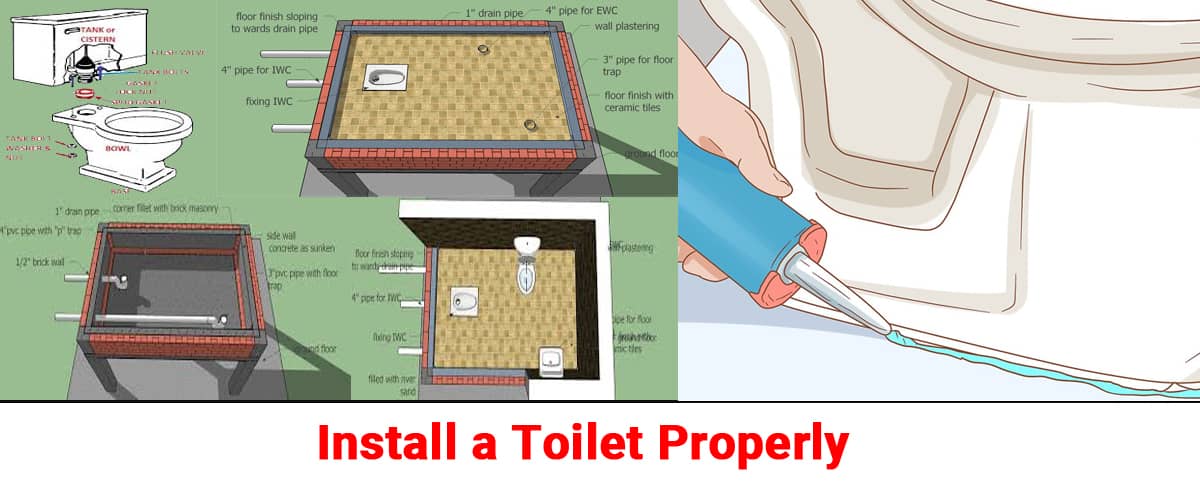

How to Install a Toilet Properly?

Toilet leaking and its related difficulties are difficult to catch without difficulty. When it comes to introducing the Toilet and its connected elements, more thought should be given.

It is nearly impossible to stop a toilet leak after it has occurred. It is necessary to demolish the entire work and replace it with a new one. As a result, caution should be exercised throughout the early stages of construction, such as providing a sunken slab, repairing pipes, and constructing a storage room.

On the ground floor, a toilet may be installed with only a few basic skills. However, in a multistory building (on the first or second floor), additional thought is required.

Right now, we'll tell you about the toilet installation in the first-floor development.

With reference photographs, we need to understand what the arrangement of Toilet Installation is. If we carefully follow this instruction, we should be able to stop the toilet from leaking.

Stage 1

Ascending of column up to ground floor rooftop (IE base of Sunken slab). Making of centring and covering work.

Stage 2

Laying of Reinforcement for base and side wall concrete. Place the spread square aimlessly and keep up the successful clear spread at base and side moreover. Supplement the side wall reinforcement in the column to capture the leakage through the column.

Stage 3

Giving Sunken slab concrete at base. Use admixtures like water sealing operator and keep up mixture ratio of 1:11/2:3 (M20 grade). sand ought to be spotless as could be expected under the circumstances.

Ensure that sand is screened through sifter and separated from sediment and undesirable minerals. Mixture of total ought to be half 10 mm in addition to half 20 mm. So that we can accomplish an appropriate blend. At that point no one but we can make the solid without nectar comp voids.

Stage 4

Giving half brick wall at external edge as covering. concrete mortar ratio must be 1:4. sand ought to be spotless as could be expected under the circumstances.

Ensure that sand is screened through sifter and separated from sediment and undesirable minerals.Curing of wall for at least 7 days. After that we can continue our next work.

Stage 5

Giving Sunken slab concrete at the side. All consideration must be followed as of now said at bottom slab placing.Use admixtures like water sealing operator and keep up mixture ratio of 1:11/2:3 (M20 grade).

The sand ought to be spotless as could reasonably be expected. Ensure that sand is screened through sifter and separated from sediment and undesirable minerals. Mixture of total ought to be half 10 mm in addition to half 20 mm. So that we can accomplish an appropriate blend.

At that point no one but we can make the solid without honeycomb voids. Place both side wall cement and column concrete on the same day with no joint.

Stage 6

Furnishing all the corners with decrease arrangement with brick workmanship to frame a bend or decrease so as to capture leakage at corner.

Stage 7

Give gaps to embeddings the sterile funnels for IWC, EWC and floor trap. Fix the necessary channels appropriately. Capture the openings with care and ensure that there is no leakage.

Stage 8

Subsequent to fixing the funnel, make putting for both side and base solid wall all the while with no joint. utilize appropriate water sealing specialists. The base floor completing must have inclining toward the 1'' pipe.

Since, if any leakage from joints of funnel, joint from tile, the released waste will be arranged consequently through this channel pipe without damping the wall. This is the reason for the little channel pipe.

This little funnel fills in as the protected gatekeeper for the whole Toilet establishment. It keeps the whole sunken slab from harm. you can comprehend by following the beneath image.

Stage 9

In the wake of making wall putting, Place Fix P trap and floor Trap and guarantee the correct degree of the pipe. Now close the external finish of all pipes with seal and top the water off to the highest point of P trap and floor trap and leave for 24 hours.

Following 24 hours, Check for any leakage. Watch the 1'' channel pipe for any stream.. In the event that there is any hole and water stream from the channel pipe, supplant the funnel work until leakage is captured.

Subsequent to getting affirmation, we can continue the following work. In the event that you don't take care right now, the toilet framework needs to be kept up for lifetime. So stage 9 procedure is a significant advance.

Stage 10

Subsequent to checking the leakage, First supplement the IWC into the p trap and apply the mortar around the Joint.( Joint methods P trap and IWC meeting point).

Fill the staying sunken slab with waterway sand up to the tallness of PCC. Combine the waterway sand with water and slam it.

Stage 11

Give the PCC 1:4:8 to a base thickness of 5''. Better to utilize broken bricks for total. since it won't harm the pipes. At the top of pcc, flooring with cm 1:3 with appropriate water sealing specialist ought to be laid.

Stage 12

Laying of Ceramic or other floor finish appropriately ought to be made up to the highest point of IWC and slanting of tile finish must towards the floor trap to pass on the water.

It's now time to fix other EWCs, wash basins, and other taps, among other things. This is the entire procedure for installing a toilet. We hope you found it beneficial. Please share your ideas and suggestions with us!