Some useful tips for reinforcement detailing

Usefultips

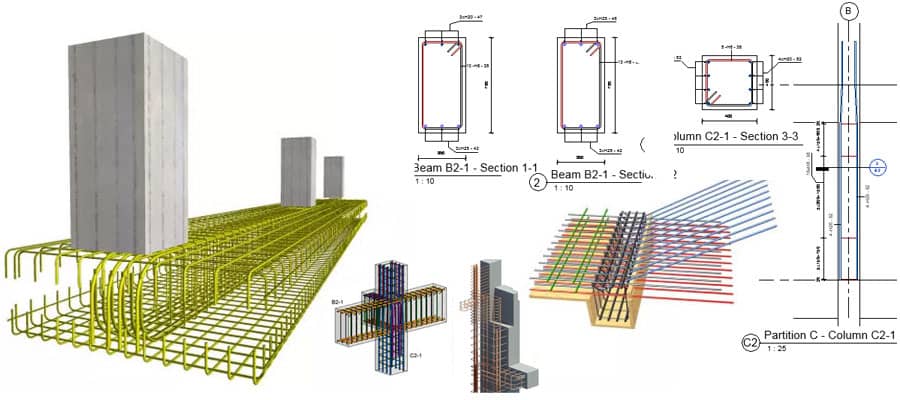

Given below, some useful tips for reinforcement detailing

Create drawings perfectly. Try to mark every bar and demonstrate its shape for transparency.

Cross section of retaining wall that falls quickly as soon as soil backfill is arranged since 1/4" dia is used instead of 1 1/4" dia. Errors happen as exact rebar dia is covered with a dimension line.

If required, generate bar bending schedule.

Denote perfect clear cover, nominal cover or effective cover to reinforcement.

Settle detailed location of opening/hole and provide sufficient information for reinforcement around the openings.

Utilize the size of bars and spirals which are easily accessible. For a single structural member, there should limited numbers of various sizes of bars.

The grade of the steel should be mentioned properly in the drawing. Deformed bars should not contain hooks at their ends.

The enlarge details at corner, intersections of walls, beams and column joint should be demonstrated at identical situations. There should not be congestion of bars at points where members overlap and ensure that all reinforcements are placed perfectly.

For bundled bars, lapped splice of bundled bars should be formed by connecting one bar at once; such separate splices inside the bundle should be staggered.

Ensure that the hooked and bent up bars are arranged and there is sufficient protection for concrete.

Specify all expansion, construction and contraction joints on plans and provide details for such joints.

The position of construction joints should be at the point of minimum shear roughly at mid or adjacent to the mid points. It should be created vertically instead of a sloped manner.

Article Source: onlinecivilforum.com