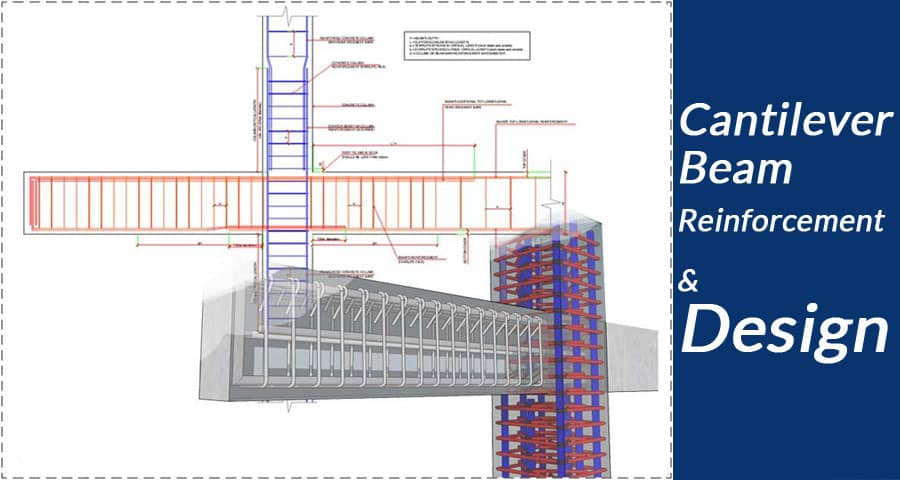

Cantilever Beam Reinforcement | Design of Cantilever Beam

A cantilever beam is a structural element that is anchored at one end and extends horizontally with the other end free. This type of beam is widely used in construction due to its ability to support loads without the need for intermediate supports, making it ideal for overhanging structures like balconies, bridges, and canopies. The design and reinforcement of cantilever beams are crucial to ensure their stability, strength, and durability.

Understanding Cantilever Beams

Cantilever beams differ from simply supported beams in that they have a fixed support at one end and no support at the other. This unique configuration means that the beam experiences both bending and shear forces, particularly at the fixed end. The design of a cantilever beam must account for these forces to prevent failure and ensure safety.

Design Considerations for Cantilever Beams

1. Load Analysis:

- Dead Loads: These include the weight of the beam itself and any permanent fixtures.

- Live Loads: These are variable forces such as people, furniture, and vehicles.

- Environmental Loads: Wind, snow, and seismic activities also influence the design.

2. Material Selection:

- The choice of material (typically steel or reinforced concrete) depends on the required strength, durability, and environmental conditions.

3. Beam Dimensions:

- Proper sizing of the beam's cross-sectional area is critical. The depth and width of the beam are determined based on the span length and the applied loads.

4. Support Conditions:

- The fixed end must be robustly anchored to prevent rotation and movement. This often involves embedding the beam into a solid support structure.

Reinforcement of Cantilever Beams

Reinforcement is essential in cantilever beams to resist tensile stresses, particularly in reinforced concrete beams. The primary reinforcement is placed at the top of the beam, where tensile stresses are greatest.

1. Steel Reinforcement:

- Main Reinforcement Bars: These are placed at the top of the beam to resist tension.

- Stirrups: These are vertical or inclined bars that help resist shear forces and prevent cracking.

- Anchorage: Proper anchorage of reinforcement bars is crucial to ensure that the bars do not slip.

2. Concrete Cover:

- Adequate concrete cover over the reinforcement bars protects them from corrosion and fire.

3. Reinforcement Detailing:

- The spacing, size, and placement of reinforcement bars must follow design codes and standards to ensure structural integrity.

Steps in Designing a Cantilever Beam

- Determine the Span Length and Load: Calculate the total load the beam must support, including dead, live, and environmental loads.

- Select Material and Beam Dimensions: Choose appropriate materials and preliminary dimensions based on load calculations and span length.

- Calculate Bending Moment and Shear Forces: Use structural analysis to determine the maximum bending moment and shear forces at the fixed end.

- Design Reinforcement: Determine the required reinforcement area using the bending moment and shear force values. Place the main reinforcement at the tension zone and design stirrups to handle shear.

- Check Deflection: Ensure that the beam's deflection under load is within acceptable limits to prevent excessive bending or sagging.

- Detailing and Drafting: Create detailed drawings showing the placement and specifications of reinforcement bars, stirrups, and anchorage.

Conclusion

The design and reinforcement of cantilever beams require careful consideration of load conditions, material properties, and structural analysis. Properly designed cantilever beams can provide robust and durable support for a variety of structures, ensuring safety and functionality. By following established design principles and reinforcement techniques, engineers can create effective cantilever beams that meet the demands of modern construction.

Please watch the following short video for Cantilever Beam Reinforcement