Optimizing concrete surfaces by minimizing evaporation

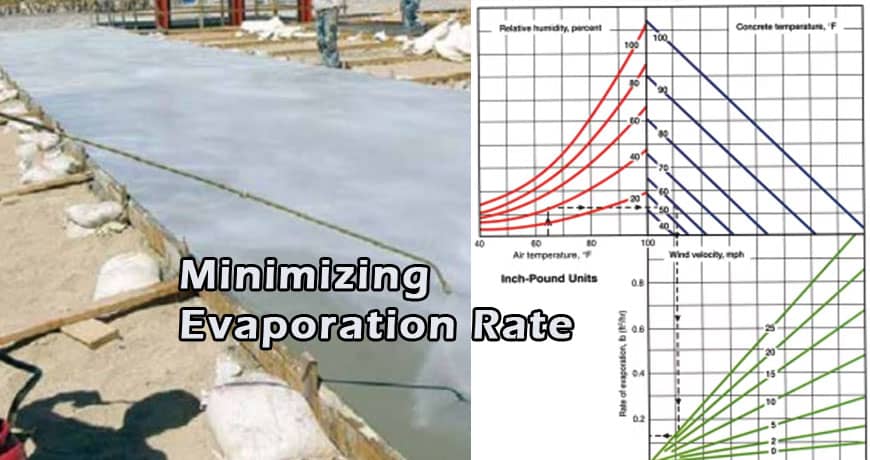

It is possible to experience quality, durability, and strength-related issues when a high rate of evaporation occurs on the concrete surface. A higher evaporation rate than 1 Kg/m2/hour increases the likelihood of plastic shrinkage cracks. If evaporation exceeds 0.5 Kg/m2/hour, appropriate measures need to be taken to slow it down.

Two variables, namely wind velocity and concrete temperature, are highly significant in determining the evaporation rate. The concrete pouring temperature can be controlled and wind effects can be avoided by taking protective measures.

Define Surface Water Evaporation

The process of evaporation involves the formation of water vapor from a free surface of the water. The concentration of water vapor decreases with increasing distance from the evaporating surface. Water vapor molecules are transferred from the evaporating surface to the ambient environment through a turbulent vertical exchange of air masses.

Effective Method of Minimize Evaporation Rate in Concrete Surface

Fogging

Water is atomized by using special nozzles, which create a fog-like mist during fogging. House wraps of this type provide a continuous drainage gap.

It is necessary to fog frequently during windy days to keep the evaporation rate as low as possible. To compensate for the moisture that prematurely evaporates from the concrete surface, fogging is a way to add water. By increasing relative humidity above concrete, the rate of evaporation is reduced.

Windbreaks & Shades

The use of shade and windbreaks can reduce the evaporation rate from concrete surfaces, resulting in higher quality concrete. It is not always possible to place shade and windbreaks on construction sites. The evaporation rate should be reduced by considering other options.

Evaporation Reducer

After striking off the concrete and between finishing operations, an evaporation reducer can help prevent surface drying if the above strategies do not work. Water and chemical compounds are used to create an oil-like coating over concrete surfaces to reduce evaporation. This reduces bleeding water's evaporation rate.

Frequency and time of application determine the effectiveness of the evaporation reducer. The evaporation rate should be reduced by applying relatively weak compounds more frequently. The subsequent bleeding causes a thin layer of surface mortar to delaminate if the evaporation reducer is applied.

Limitation of Evaporation Reducer

It is not recommended to work the evaporation reducer into the concrete surface. The reason is because a mixture with 90 percent water can alter the water-cement ratio along its surface, posing a risk to its durability and quality.

As soon as the sheen on the concrete surface disappears, such materials should be used. Under conditions where the evaporation rate exceeds the bleeding rate, the supervisor should distinguish between the disappearances of the sheen that occurs when bleeding stops. Bleeding water evaporates from the apparent loss of sheen before bleeding stops.

How Water Evaporate in Surface Concrete?

Temperature affects the rate at which concrete's water evaporates due to higher temperatures leading to more evaporation. The higher the evaporation rate is the greater the slump loss will be. There is good documentation and a relatively good understanding of evaporation rates.

Wrapping it Up

In addition to shading and windbreaks, fogging and evaporation reducers can also be used to control evaporation. The evaporation rate in the shade is naturally lower than in places exposed to the sun's rays. An evaporation reducer can be used if the site conditions do not allow these methods. In addition to reducing wind velocity, windbreaks also reduce evaporation rates.