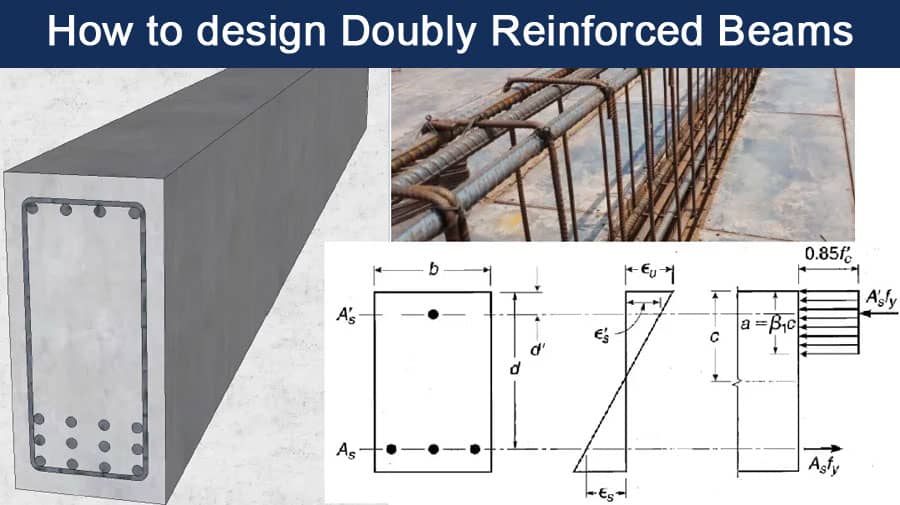

How to design Doubly Reinforced Beams

Designing doubly reinforced beams can be a challenging task, even for seasoned structural engineers. However, with the right knowledge and tools, anyone can design these beams with ease. In this article, we will discuss the key steps involved in designing doubly reinforced beams, along with some important tips to help you achieve optimal results.

What are doubly reinforced beams?

Before we dive into the design process, let's first understand what doubly reinforced beams are. As the name suggests, these beams are reinforced with two sets of steel bars, one in tension and one in compression. The purpose of using two sets of reinforcement is to increase the load-bearing capacity of the beam.

Step-by-Step Design Process

Determine the design loads

The first step in designing any beam is to determine the design loads. These loads include dead load, live load, and any other imposed loads. Dead load is the weight of the structure itself, while live load is the weight of people, furniture, and other movable objects. Imposed loads can include wind loads, earthquake loads, and snow loads.

Calculate the factored loads

Once you have determined the design loads, you need to calculate the factored loads. Factored loads are the loads that the beam will actually experience during its lifetime, and are calculated by multiplying the design loads by a load factor.

Select a suitable beam section

The next step is to select a suitable beam section that can resist the factored loads. This involves calculating the required moment of resistance and selecting a beam section that can provide the required resistance. The moment of resistance is the ability of the beam to resist bending under load.

Determine the effective depth

The effective depth is the distance from the extreme compression fiber to the centroid of the tension steel. This is an important parameter in beam design as it affects the moment of resistance of the beam. The effective depth can be calculated using the formula d = (M/f_ck*b), where M is the factored bending moment, f_ck is the characteristic strength of concrete, and b is the width of the beam.

Determine the area of tension reinforcement

Once you have determined the effective depth, you need to calculate the area of tension reinforcement required to resist the factored bending moment. This can be done using the formula Ast = (M/(0.87fy(d-d/3))), where M is the factored bending moment, fy is the yield strength of the steel, and d is the effective depth.

Check for deflection and shear

Finally, you need to check the beam for deflection and shear. Deflection is the bending of the beam under load, while shear is the force acting perpendicular to the axis of the beam. Both deflection and shear can cause failure of the beam if not properly accounted for in the design.

Tips for Designing Doubly Reinforced Beams

Use high-quality materials

When designing doubly reinforced beams, it is important to use high-quality materials. This includes high-strength concrete and steel with a high yield strength. Using subpar materials can compromise the safety and durability of the beam.

Pay attention to detailing

Detailing is an important aspect of beam design that should not be overlooked. Proper detailing can help ensure that the reinforcement is placed correctly and that the beam is strong and durable. This includes ensuring proper cover to the reinforcement, using appropriate lap lengths, and providing proper anchorage.

Consider construction constraints

Construction constraints, such as limited space and access, can make the design and construction of doubly reinforced beams challenging. It is important to consider these constraints during the design process and come up with a design that can be feasibly constructed.

Seek expert advice

Designing doubly reinforced beams is an essential skill for any structural engineer or architect. The design process involves a careful consideration of several factors, including the beam's load-carrying capacity, the type and quality of materials used, and the dimensions of the beam itself.

At its core, a doubly reinforced beam is a reinforced concrete beam that has both tension and compression reinforcement. The compression reinforcement is typically provided in the form of longitudinal bars, while the tension reinforcement consists of a combination of transverse bars and stirrups.

To design a doubly reinforced beam, one must first calculate the load-carrying capacity of the beam. This involves determining the beam's moment of inertia, which is a measure of the beam's resistance to bending. The moment of inertia is calculated by multiplying the area of the cross-section of the beam by the square of the distance between the centroid of the cross-section and the neutral axis.

Once the moment of inertia has been calculated, the required amount of tension and compression reinforcement can be determined. This is done by using the yield strength of the reinforcement and the moment of the applied loads.

One of the essential aspects of designing doubly reinforced beams is ensuring that the reinforcement bars are appropriately spaced and adequately anchored. This is achieved by using a combination of transverse bars and stirrups, which help to hold the reinforcement bars in place and distribute the load evenly throughout the beam.

When designing doubly reinforced beams, it is also crucial to consider the type and quality of materials used. The concrete used must have a specified compressive strength, which is typically determined by performing compression tests on samples of the concrete.

The reinforcement bars used in the beam must also meet certain specifications, including their yield strength, size, and spacing. Additionally, the bars must be properly coated to prevent corrosion, which can weaken the overall structure of the beam over time.