Detailed Design of Trusses | Design of Roof Trusses

Roof trusses are an essential structural component in modern construction, offering support and stability to a variety of building types. The design of roof trusses requires careful consideration of materials, geometry, and load distribution to ensure safety, durability, and cost-effectiveness.

Understanding the Basics of Truss Design

What is a Truss?

A truss is a framework composed of triangles that work together to support loads. The triangular arrangement of the elements provides stability and allows the truss to evenly distribute weight across its structure. Trusses are commonly used in roofs, bridges, towers, and other structures requiring support over long spans.

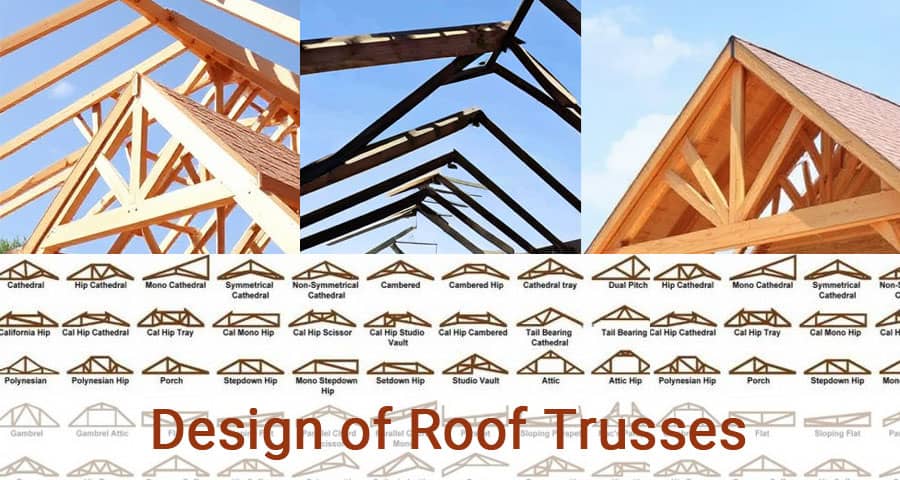

Types of Roof Trusses

Roof trusses come in various designs, each suited to different applications and architectural requirements. The most common types include:

- King Post Truss: A simple and economical design often used for short spans.

- Queen Post Truss: A variation of the King Post, suitable for slightly longer spans.

- Howe Truss: Characterized by diagonal members sloping towards the center, ideal for supporting heavy loads.

- Pratt Truss: Features diagonals that slope towards the outside, commonly used in industrial and residential buildings.

- Fink Truss: A widely used design in residential construction, providing efficient load distribution.

Key Considerations in Truss Design

Load Calculations

One of the most critical aspects of truss design is calculating the loads the structure will bear. These loads include:

- Dead Loads: The weight of the truss itself, along with any permanent fixtures attached to it.

- Live Loads: The weight of temporary elements, such as snow, wind, and occupants.

- Environmental Loads: Factors like wind pressure, snow accumulation, and seismic activity.

Accurate load calculations are essential to ensure that the truss can withstand these forces without compromising structural integrity.

Material Selection

The choice of materials plays a crucial role in the performance and longevity of a truss. Common materials used in truss construction include:

- Timber: Widely used in residential construction, offering a good balance of strength, weight, and cost.

- Steel: Preferred for commercial and industrial applications due to its high strength-to-weight ratio and durability.

- Aluminum: Used in specialized applications where weight reduction is critical, such as in aircraft hangars.

Each material has its advantages and limitations, and the selection process should consider factors like load requirements, environmental conditions, and budget.

Geometry and Span

The geometry of a truss, including the shape and length of its members, significantly impacts its ability to bear loads. The span of the truss - the distance it covers between supports - determines the design and complexity of the structure. Longer spans require more intricate designs to distribute the weight evenly and prevent sagging.

Connection Details

The joints and connections in a truss are critical to its overall performance. These connections must be designed to transfer loads between members effectively, without causing undue stress or movement. Common types of connections include:

- Bolted Connections: Simple and effective, often used in timber and steel trusses.

- Welded Connections: Provide strong and rigid joints, commonly used in steel trusses.

- Gusset Plates: Metal plates used to reinforce connections, particularly in complex truss designs.

Deflection Limits

Deflection refers to the amount a truss bends or sags under load. Limiting deflection is essential to prevent structural damage and ensure the truss functions as intended. Engineers must calculate the expected deflection based on load and material properties, ensuring it stays within acceptable limits.

Steps in Designing a Roof Truss

Step 1: Define the Requirements

The first step in designing a roof truss is to define the requirements of the project. This includes understanding the building's architectural plans, load requirements, and any specific design constraints. Clear communication with the client and other stakeholders is essential at this stage.

Step 2: Choose the Truss Type

Based on the project requirements, the next step is to choose the appropriate truss type. Consider factors like span length, load distribution, and aesthetic preferences. The chosen truss type will guide the rest of the design process.

Step 3: Perform Load Analysis

Conduct a detailed load analysis to determine the forces that will act on the truss. This includes calculating dead loads, live loads, and environmental loads. Software tools like Finite Element Analysis (FEA) can be used to simulate load distribution and identify potential stress points.

Step 4: Select Materials

Choose the materials for the truss based on the load analysis and project requirements. Consider factors like cost, availability, and environmental impact. The selected materials should be capable of withstanding the calculated loads without excessive deflection or failure.

Step 5: Design the Truss Geometry

Design the truss geometry, including the shape and size of each member. The goal is to create a structure that efficiently distributes loads while minimizing material use. Pay attention to the spacing of the members, the angles of the connections, and the overall symmetry of the design.

Step 6: Detail the Connections

Detail the connections between the truss members, ensuring they are strong enough to transfer loads without failure. Consider using gusset plates, bolts, or welding to reinforce the joints, depending on the materials used.

Step 7: Check Deflection and Stress

Verify that the truss design meets deflection and stress limits. If necessary, adjust the geometry or materials to reduce deflection or redistribute stress. This step is crucial to ensure the truss will perform as expected under real-world conditions.

Step 8: Finalize the Design

Once all checks are complete, finalize the truss design and prepare detailed drawings and specifications for construction. Ensure that all aspects of the design are well-documented, including load calculations, material specifications, and connection details.

Advantages of Using Trusses in Roof Design

Cost-Effective Construction

Trusses allow for cost-effective construction by minimizing the amount of material needed to achieve structural stability. The triangular geometry of trusses distributes loads efficiently, reducing the need for additional support structures.

Versatility in Design

Trusses offer versatility in design, allowing architects and engineers to create structures with long spans and unique shapes. This flexibility makes trusses a popular choice in both residential and commercial construction.

Ease of Installation

Prefabricated trusses can be manufactured off-site and delivered to the construction site for easy installation. This reduces construction time and labor costs, making trusses an attractive option for many projects.

Durability and Strength

When designed correctly, trusses provide excellent durability and strength, capable of withstanding heavy loads and harsh environmental conditions. The use of high-quality materials and precise engineering ensures that trusses remain stable and reliable over time.

Conclusion

The detailed design of trusses is a critical aspect of modern construction, requiring careful consideration of loads, materials, geometry, and connections. By following a systematic design process and paying attention to key factors, engineers can create trusses that provide both strength and efficiency.

Please watch the following short video for Design of Roof Trusses