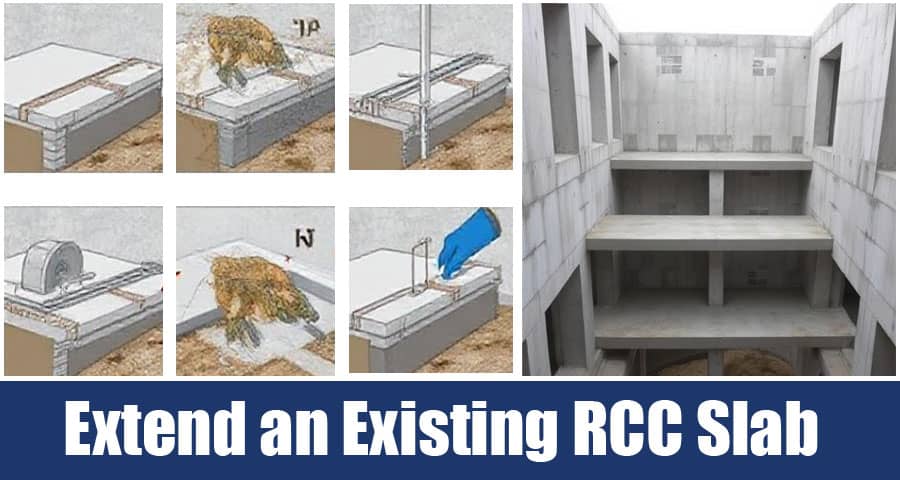

How Can We Extend an Existing RCC Slab?

When we are faced with spatial limitations in a building, one of the most effective solutions is to extend an existing RCC (Reinforced Cement Concrete) slab. This process, however, demands detailed structural planning, expert design considerations, and adherence to civil engineering standards to maintain the safety and longevity of the structure.

Understanding the Purpose and Scope of RCC Slab Extension

Before initiating any extension project, it is essential to conduct a thorough feasibility study. The nature of the extension - whether for an additional room, a balcony, or increased load-bearing capacity - greatly influences the method to be used. We must assess:

- Structural capacity of the existing slab

- Load distribution of the extension

- Design compatibility with the existing structure

- Compliance with building codes and regulations

Structural Assessment of the Existing RCC Slab

A detailed structural audit is the first step before any extension. We must evaluate:

- Concrete grade and strength using non-destructive tests like rebound hammer and core cutting.

- Condition of reinforcement bars (rebars) to detect corrosion, fatigue, or stress cracks.

- Existing load vs. design load of the slab.

- Support system - whether the slab is simply supported, continuous, or cantilevered.

This assessment informs the structural designer if the slab can safely support additional loads or if reinforcement is necessary.

Design and Load Calculations for the Extension

The design stage involves precise load calculations:

- Dead load (self-weight of the structure)

- Live load (furniture, occupancy)

- Superimposed loads (floor finishes, partitions)

- Environmental loads (wind, seismic activity, temperature variation)

A structural engineer uses this data to determine the type of extension feasible - whether it's an independent slab, a cantilever extension, or an integrated structural extension. Software such as STAAD Pro, ETABS, or AutoCAD Civil 3D is typically used for simulation and analysis.

Methods for Extending an RCC Slab

We outline the most common construction methods for slab extension:

1. Cantilever Slab Extension

A cantilever slab projects out from the existing slab without external supports.

- Requires extension of reinforcement bars from the existing slab, or new anchor bars fixed with chemical bonding agents like Hilti RE 500 or Fosroc Nitobond EP.

- Suitable for small balconies or overhangs (typically up to 1.5 meters).

- Critical to balance the moment created by the cantilever with the structural counterweight on the other side.

2. Beamed Slab Extension

In this method, a new slab is cast on beams integrated with the existing structure.

- Beams are anchored to columns or walls.

- Offers better load distribution and can support heavier or longer slab extensions.

- Ideal for room additions or significant structural changes.

3. Slab-on-Beam with Additional Column Support

When extending beyond 2 meters, it's advisable to include additional columns to support the extended slab.

- Provides maximum structural integrity.

- Allows flexible load design and prevents undue stress on the old slab.

- Suitable for load-bearing slab extensions, such as rooms with masonry walls.

Reinforcement Techniques and Detailing

Proper reinforcement is critical to the success of any slab extension. We must ensure:

- Lapping of reinforcement bars is adequate (typically 50d for tension bars, where d is the bar diameter).

- Anchoring of new bars into the old slab using mechanical couplers or chemical anchors.

- Shear keys or roughening of the old slab surface to create a better bond.

- Use of anti-corrosive coatings on rebars to prevent future degradation.

Formwork and Concreting Process

The formwork must be properly aligned and securely supported, especially if working on cantilever slabs. Key practices include:

- Use plywood with steel supports for formwork.

- Ensure minimum deflection and vibration during concrete pouring.

- Maintain correct water-cement ratio to avoid shrinkage cracks.

- Employ vibrators for compacting concrete, ensuring there are no air pockets.

- Cure concrete for a minimum of 14 days to develop adequate strength.

Bonding Techniques for Integrating New and Old Concrete

Bonding the old and new concrete is a critical challenge. To achieve a monolithic structure, we recommend:

- Cleaning the old concrete surface thoroughly to remove dust, grease, or laitance.

- Applying a bonding agent such as polymer-modified slurry or epoxy.

- Drilling and installing dowel bars that tie the new concrete into the old slab.

- Maintaining joint alignment and sealing construction joints properly.

Dealing with Architectural and Finishing Concerns

Once the slab extension is structurally sound, focus shifts to:

- Level matching between the old and new slab.

- Waterproofing the extended area using membranes, coatings, or bitumen layers.

- Thermal insulation if the extension is exposed to external weather conditions.

- Aesthetic integration with the rest of the building through plastering, tiling, and painting.

Approval, Legal, and Safety Considerations

Extending an RCC slab without official permissions can lead to legal complications. Always:

- Consult local building authorities for required permits.

- Ensure the extension complies with zoning laws and structural safety codes.

- Hire licensed professionals for structural design and execution.

- Conduct site safety audits and adhere to construction site regulations.

Common Mistakes to Avoid in RCC Slab Extension

- Ignoring load-bearing calculations before beginning construction.

- Failing to use proper bonding techniques between old and new concrete.

- Not consulting a qualified structural engineer.

- Extending slabs without considering lateral support.

- Using inadequate formwork or curing practices.

Conclusion

Extending an existing RCC slab is a highly technical procedure that requires a meticulous balance between design, execution, and safety. With the right approach - anchored in structural analysis, professional design, and proper construction methodology - we can achieve durable, load-resistant, and legally compliant slab extensions that enhance both functionality and aesthetics of any structure.

Please watch following short video for extend an existing RCC slab