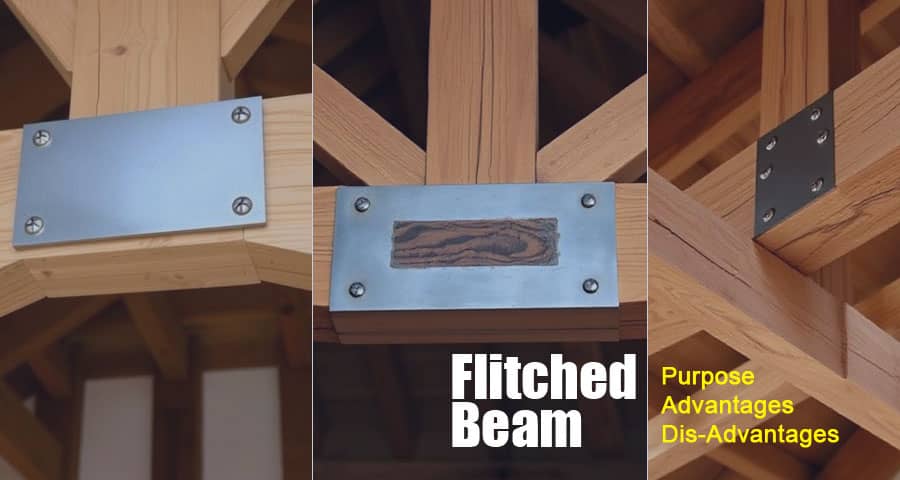

What is a Flitched Beam? Its Purpose, Advantages, Disadvantages, and Applications

In the field of structural engineering, one component that has stood the test of time due to its unique composition and enhanced strength is the flitched beam. A flitched beam is a composite structural element commonly used in construction to combine the aesthetic and flexibility of timber with the strength and durability of steel. This hybrid design allows for greater load-bearing capacity without compromising on traditional architectural appeal.

Understanding Flitched Beams in Structural Engineering

A flitched beam, also known as a composite beam, typically consists of a steel plate sandwiched between two timber beams, all securely bolted together to function as a single unit. The steel plate, often mild steel, serves to increase the stiffness and load-bearing capacity of the timber beams, while the timber provides ease of handling, insulation, and a traditional appearance.

These beams are especially useful in renovation projects, heritage structures, and new constructions where wood is the preferred exterior material but added structural support is necessary.

Purpose of a Flitched Beam

The primary purpose of using a flitched beam is to enhance structural capacity without resorting to large and unwieldy solid steel or concrete alternatives. Here's what makes them invaluable:

- Load-bearing enhancement: They carry heavier loads than traditional timber beams.

- Flexural strength: Improved resistance to bending under weight.

- Aesthetic preservation: Maintain the visual warmth of wood in exposed beams.

- Retrofitting solution: Ideal for upgrading existing timber structures without altering their appearance drastically.

Flitched beams are frequently used in roof construction, floor joists, bridge decks, and even heavy-duty shelves and frameworks.

Advantages of Flitched Beams

1. Increased Load-Carrying Capacity

The combination of steel's tensile strength with timber's compressive ability results in a beam that can support significantly more weight than either material alone. This makes it ideal for structures where traditional timber would fail under load.

2. Reduction in Beam Depth

Because of their enhanced strength, flitched beams can be designed with reduced depth, making them suitable for architectural scenarios where vertical space is limited, such as attics or low-ceilinged rooms.

3. Improved Fire Resistance (With Protection)

Though steel by itself conducts heat, when embedded within timber and properly insulated, flitched beams can offer improved fire resistance. Timber chars on the outside during a fire, which can protect the inner steel plate for a longer duration compared to exposed steel beams.

4. Cost-Effective Alternative

Instead of using a full steel beam (which might require skilled labor and expensive handling equipment), a flitched beam is easier to fabricate on-site, uses less steel, and thus becomes more cost-effective in small- to mid-scale projects.

5. Design Flexibility

Flitched beams allow for architectural versatility, enabling designers to retain the natural wood finish while achieving the mechanical performance closer to that of structural steel.

6. Ease of Retrofitting

One of the most significant advantages is in strengthening existing wooden beams. A flitch plate can be added to an older timber beam to enhance its performance without the need for complete replacement.

Disadvantages of Flitched Beams

1. Complex Fabrication Process

While the concept is simple, the actual fabrication and installation of flitched beams require precision engineering. The alignment of the timber and steel, proper bolting techniques, and equal load sharing are critical. Mistakes in execution can lead to uneven stress distribution.

2. Corrosion of Steel Plate

The embedded steel plate, if not properly treated or protected, is susceptible to moisture-induced corrosion, especially in environments with high humidity or poor ventilation.

3. Increased Weight Compared to Timber Alone

While lighter than pure steel beams, flitched beams are heavier than timber-only beams, which can be a disadvantage during manual handling or in areas where load restrictions are applied during transport or installation.

4. Higher Initial Cost Than Solid Timber

Despite being more economical than full steel alternatives, flitched beams are costlier than solid timber beams. This could be a consideration in projects with very tight budgets.

5. Bolting Requirements and Stress Distribution

To ensure the beam acts as a single unit, adequate bolting at proper intervals is essential. Improper bolting can lead to slippage between the materials, thereby reducing the efficiency of the composite action.

Applications of Flitched Beams

Flitched beams are found in numerous construction contexts where a blend of aesthetics and strength is desired. Common applications include:

- Historic building restorations

- Timber-framed homes and cabins

- Churches and temples with large wooden roof spans

- Commercial interiors with exposed beam ceilings

- Floor joists requiring reinforcement

- Bridge reinforcements in rural or semi-urban areas

Their use is particularly prominent in architectural designs that aim to preserve traditional looks while adhering to modern building codes and safety standards.

Design Considerations for Flitched Beams

When incorporating flitched beams into a structural design, engineers must consider:

- Material compatibility: Timber and steel should have similar deflection characteristics to avoid stress concentration.

- Connection design: The bolts must be designed to prevent relative movement and ensure uniform stress distribution.

- Environmental protection: Timber must be treated against rot and insects, and steel must be galvanized or coated to prevent rust.

- Load analysis: Both dead loads and live loads should be accounted for during beam sizing.

- Fire safety codes: Fire-resistant coatings or claddings may be required depending on local regulations.

Conclusion

The flitched beam stands as a prime example of composite engineering that brings together the best of both timber and steel. Whether it's for residential, commercial, or heritage restoration projects, flitched beams offer an ideal solution for situations requiring increased strength without sacrificing aesthetic integrity. While they do have some drawbacks, proper design, fabrication, and maintenance can make flitched beams a long-lasting, high-performance choice in modern construction.

Please watch the following short video for Flitched Beam