Understanding Mechanical Couplers in Construction

In the world of construction, every connection matters. The strength and integrity of a building often rely on the connections between various structural elements. One crucial component in this regard is the mechanical coupler. So, let's fasten our knowledge belts and dive into the nuts and bolts of mechanical couplers!

Introduction

In the world of construction, where strength and safety are paramount, every connection between structural elements plays a crucial role. Mechanical couplers are essential components that facilitate strong and reliable connections in reinforced concrete structures. Let's explore the world of mechanical couplers and how they contribute to the stability of buildings.

What Are Mechanical Couplers?

Mechanical couplers, also known as rebar couplers or reinforcement couplers, are devices used to connect two pieces of reinforcing steel bars (rebar) without the need for lapped splices. These couplers are designed to transfer loads from one bar to another effectively. They come in various types and are employed in different construction scenarios, enhancing the structural integrity of buildings.

Types of Mechanical Couplers

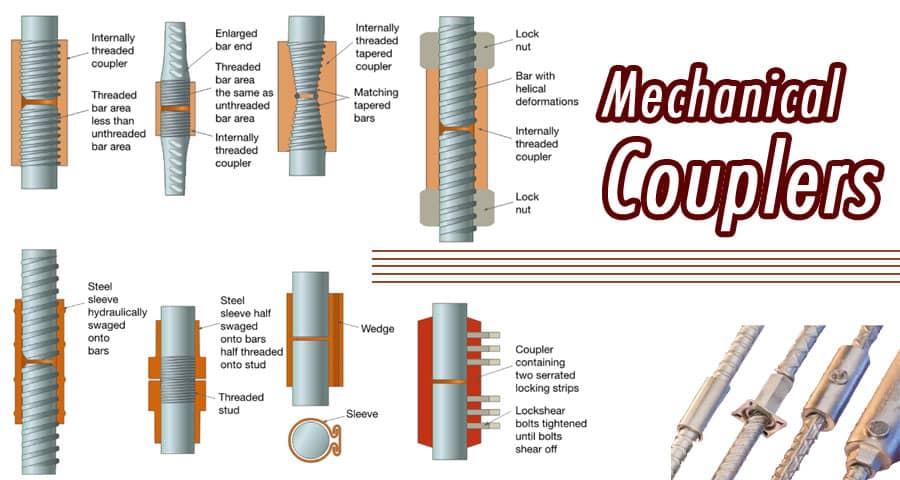

- Threaded Rebar Couplers: Threaded rebar couplers are among the most commonly used mechanical couplers. They consist of two threaded sleeves that are screwed onto the ends of the rebar to be joined. Once the sleeves are properly tightened, they create a secure connection, ensuring the load is transferred efficiently.

- Grout-Filled Couplers: Grout-filled couplers involve the use of a hollow steel sleeve that fits over the ends of the rebar. The space within the sleeve is filled with grout, forming a solid connection between the bars. This type of coupler provides excellent load transfer capabilities and is often used in high-stress applications.

- Bolted Couplers: Bolted couplers utilize bolts or shear pins to connect rebar ends. They are relatively easy to install and offer flexibility in terms of adjusting the connection length. Bolted couplers are often used in situations where the rebar needs to be adjusted or replaced.

Advantages of Using Mechanical Couplers

The use of mechanical couplers offers several advantages in construction:

- Improved structural integrity

- Enhanced load transfer capacity

- Reduction in construction time

- Elimination of lapped splices

- Minimized congestion of reinforcing bars

- Cost savings in labor and materials

Installation of Mechanical Couplers

- Threaded Coupler Installation: Installing threaded couplers involves threading the rebar ends and then attaching the coupler sleeves securely. This method is widely used due to its reliability and ease of installation.

- Grout-Filled Coupler Installation: Grout-filled couplers require the sleeves to be filled with grout after fitting them over the rebar ends. Proper grouting is essential for achieving a strong connection.

Quality Control and Testing

- Tensile Testing: Tensile testing is performed to ensure that the mechanical couplers can withstand the required loads. It involves subjecting the coupled rebar to tension to verify their strength.

- Visual Inspection: Visual inspections are conducted to check for any defects or imperfections in the coupler installation. This step ensures the quality and reliability of the connections.

Common Applications of Mechanical Couplers

Mechanical couplers find application in various construction projects, including:

- High-rise buildings

- Bridges

- Industrial structures

- Infrastructure projects

- Pre-cast concrete elements

Challenges and Considerations

While mechanical couplers offer numerous benefits, it's essential to consider challenges such as proper installation, quality control, and compliance with local building codes. Additionally, selecting the appropriate coupler type for a specific project is crucial.

Future Trends in Mechanical Couplers

The construction industry is continually evolving, and so are the technologies and materials used. Future trends in mechanical couplers may include advancements in materials, improved installation methods, and enhanced compatibility with modern construction techniques.

Conclusion

Mechanical couplers play a pivotal role in ensuring the strength and stability of reinforced concrete structures. By allowing for efficient rebar connections, they contribute to safer and more resilient buildings. Whether you're constructing a towering skyscraper or a sturdy bridge, mechanical couplers are a vital component in modern construction.

FAQs

Are mechanical couplers stronger than traditional lap splices?

Mechanical couplers are designed to provide strong and reliable connections, often outperforming traditional lap splices in terms of load transfer capacity.

Can mechanical couplers be used in retrofitting projects?

Yes, mechanical couplers can be used in retrofitting projects to enhance the load-bearing capacity of existing structures.

What is the lifespan of a mechanical coupler connection?

The lifespan of a mechanical coupler connection is typically equivalent to the lifespan of the concrete structure it is a part of, provided it is properly installed and maintained.

Are there any size limitations for using mechanical couplers?

Mechanical couplers come in various sizes to accommodate different rebar diameters, so there are options available for various construction needs.

Do mechanical couplers require special training for installation?

While installation procedures for mechanical couplers should be followed carefully, they do not necessarily require specialized training. However, proper training is recommended to ensure correct installation and compliance with safety standards.