Various Types of Structural Steel Shapes | Sizes for Steel I-Beams

Structural steel is a crucial material in the construction industry, offering unparalleled strength, durability, and versatility. Among the many forms of structural steel, I-beams stand out due to their widespread use in a multitude of applications, ranging from small residential projects to large-scale commercial developments.

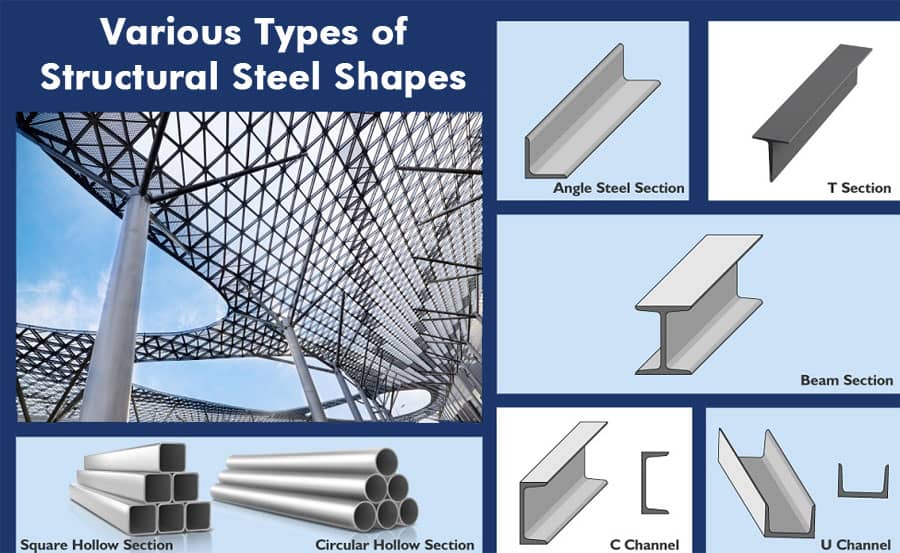

Understanding Structural Steel Shapes

Structural steel comes in a variety of shapes and sizes, each designed to meet specific engineering requirements. The most common shapes include:

a. I-Beams (H-Beams)

I-beams, also known as H-beams, W-beams, or universal beams, are named for their distinctive "I" shape when viewed from the end. They are widely used due to their high load-bearing capacity, which makes them ideal for supporting heavy structures such as bridges, buildings, and towers. I-beams are characterized by their:

- Flanges: The horizontal elements of the beam that resist bending.

- Web: The vertical element that connects the flanges and resists shear forces.

b. Angle (L-Shaped)

Angle beams are L-shaped and are used in applications requiring a strong corner reinforcement. They are commonly found in frameworks and can be used both as load-bearing components and as part of the aesthetic design.

c. Channels (C-Shaped)

Channel beams have a C-shaped cross-section and are often used for structural support in building frames, bridges, and machinery. They provide excellent resistance to bending and are often employed in conjunction with other steel shapes.

d. Tubes and Pipes (Hollow Sections)

Tubes and pipes, while similar in appearance, have different applications. Tubes are typically used in structural applications, while pipes are used for the conveyance of fluids. Both can be round, square, or rectangular in shape.

e. T-Beams

T-beams are used primarily in construction where a T-shaped cross-section is required. They are commonly used in roofing systems and in building frameworks where space constraints demand a compact yet strong support structure.

Types of Steel I-Beams

Steel I-beams are categorized based on their dimensions, the thickness of their flanges, and the height of their webs. Here are the most common types:

a. Standard I-Beams

Standard I-beams, also known as S-beams, have tapered flanges that become narrower as they extend outward from the web. They are ideal for use in situations where the primary load comes from bending forces.

b. Wide Flange Beams

Wide flange beams (W-beams) have flanges that are nearly parallel to one another, offering greater load-bearing capacity than standard I-beams. These beams are commonly used in building construction and other large structures where heavy loads are anticipated.

c. H-Pile Beams

H-pile beams are similar to wide flange beams but are typically used in deep foundation applications, such as supporting bridges, piers, and heavy buildings. They are driven into the ground and provide strong vertical support.

d. Junior Beams

Junior beams are smaller versions of standard I-beams, used in lighter applications where full-sized beams are not necessary. They are often found in residential construction and smaller commercial projects.

Sizes and Dimensions of Steel I-Beams

The size of a steel I-beam is typically specified by its height, flange width, and web thickness. The following are common sizes:

a. Depth and Flange Width

- 6x6 I-Beams: Typically used in small residential projects, these beams have a depth and flange width of 6 inches.

- 10x10 I-Beams: Common in medium-sized commercial buildings, these beams offer a balance between strength and size.

- 14x14 I-Beams: Used in large construction projects, these beams provide substantial load-bearing capacity.

b. Web Thickness

- 0.25 inches: Thin web beams are used in light structural applications.

- 0.5 inches: Medium web beams are standard for most commercial projects.

- 1 inch: Thick web beams are reserved for heavy industrial applications where maximum strength is required.

c. Lengths

Steel I-beams are manufactured in various lengths, typically ranging from 10 feet to 100 feet, depending on the requirements of the project. Custom lengths can also be fabricated to meet specific needs.

Applications of Steel I-Beams

Steel I-beams are indispensable in various construction and engineering applications. Their ability to support heavy loads while minimizing the use of material makes them a cost-effective choice for:

a. Building Frameworks

I-beams form the backbone of many buildings, providing the main support structure for walls, floors, and roofs. Their high strength-to-weight ratio allows for large spans with minimal material usage.

b. Bridges

In bridge construction, I-beams are used to support the roadway and distribute the load to the piers. Their durability and strength make them ideal for this purpose, especially in large-scale infrastructure projects.

c. Industrial Platforms

In industrial settings, I-beams are used to create platforms and mezzanines that can support heavy machinery and equipment. Their robustness ensures safety and stability in environments where heavy loads are common.

d. Warehousing and Storage Systems

I-beams are often used in the construction of storage systems, including pallet racking and mezzanine floors. Their ability to support significant loads without deformation makes them ideal for these applications.

Choosing the Right Steel I-Beam for Your Project

When selecting a steel I-beam for a project, several factors must be considered to ensure optimal performance:

a. Load Requirements

Understanding the load the beam will bear is crucial. This includes both the static loads (permanent) and dynamic loads (temporary or moving). The beam must be selected based on its ability to support these loads without excessive deflection or failure.

b. Environmental Conditions

Consideration must be given to the environment in which the beam will be used. In corrosive environments, such as near the ocean or in industrial settings, corrosion-resistant coatings or special steel grades may be necessary.

c. Budget Constraints

While it's essential to choose the right beam for the job, budget constraints often play a role in the selection process. Balancing the need for strength and durability with cost-effectiveness is key to a successful project.

d. Compliance with Standards

All structural steel used in construction must comply with local and international standards. These standards ensure that the steel has the necessary properties to perform safely and effectively in its intended application.

Conclusion

Steel I-beams are a fundamental component of modern construction, offering unmatched strength and versatility. Whether used in the framework of buildings, the construction of bridges, or the creation of industrial platforms, I-beams provide the structural integrity needed to support heavy loads and ensure the longevity of the structure. By understanding the various types and sizes of I-beams available, and selecting the right beam for each application, you can ensure that your construction project meets all necessary requirements for safety, durability, and cost-effectiveness.