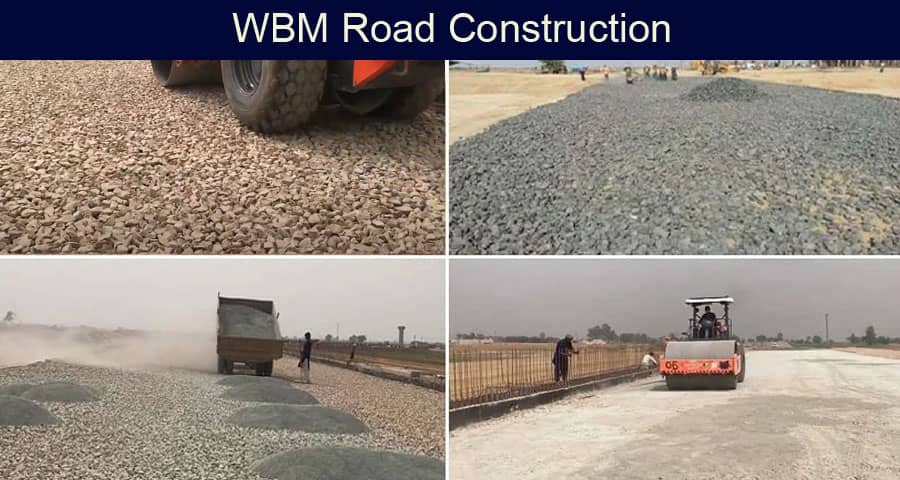

The Ultimate Guide to Water Bound Macadam Road Construction

Welcome to our comprehensive guide on Water Bound Macadam Road Construction. Whether you're a seasoned civil engineer or someone looking to gain insights into road construction, this article is for you.

Understanding Water Bound Macadam

What is Water Bound Macadam?

Water Bound Macadam (WBM) is a type of road construction method that dates back to the early 19th century. It involves the use of well-graded aggregates, such as broken stones, mixed with filler material and water to form a tightly compacted layer. WBM roads are known for their strength, durability, and ability to withstand heavy traffic loads.

Key Components of WBM

- Aggregates: Aggregates are the primary component of WBM roads. These include broken stones of various sizes, ranging from coarse to fine. The aggregates provide stability and strength to the road structure.

- Filler Material: Filler material, typically consisting of screenings or sand, is used to fill the voids between the aggregates. It helps in binding the aggregates together and enhancing the compactness of the road.

- Water: Water is essential for the construction of WBM roads as it helps in the compaction process. Proper moisture content is crucial to achieve the desired density and strength of the road.

Construction Process

- Site Preparation: The first step in constructing a WBM road is to prepare the site. This involves clearing the area of any vegetation, debris, or obstacles that may hinder the construction process. The site is then leveled and compacted to provide a stable base for the road.

- Sub-Base Construction: Once the site is prepared, the sub-base layer is constructed using a suitable material such as gravel or murram. This layer acts as a foundation for the WBM road and provides additional support.

- Aggregate Spreading: The aggregates are spread evenly over the prepared sub-base layer to the required thickness. Care is taken to ensure uniform distribution and proper gradation of the aggregates.

- Compaction: Compaction is a critical step in the construction of WBM roads. Heavy rollers are used to compact the aggregates thoroughly, ensuring maximum density and stability.

- Application of Filler Material: After compaction, the filler material is applied over the compacted aggregates. It fills the voids between the aggregates and helps in binding them together.

- Final Compaction and Surface Finishing: Once the filler material is applied, the road is compacted again to achieve the desired density. The surface is then finished using a mechanical broom or grader to provide a smooth and uniform finish.

Advantages of Water Bound Macadam Roads

- Cost-Effective: WBM roads are relatively inexpensive to construct compared to other types of road surfaces.

- Durability: WBM roads are known for their durability and ability to withstand heavy traffic loads.

- Easy Maintenance: Maintenance of WBM roads is straightforward and cost-effective, making them an ideal choice for rural areas.

- Environmentally Friendly: WBM roads require fewer natural resources and have minimal impact on the environment compared to asphalt or concrete roads.

For more information, please watch the following video tutorial

Source: Surveying Engineering Design Information

Conclusion

Water Bound Macadam road construction is a time-tested method that offers durability, strength, and cost-effectiveness. By following the proper construction techniques and using quality materials, WBM roads can provide reliable transportation infrastructure for years to come.