Why Crank Bars Are Provided In Slabs, Beams and Columns?

Introduction to Crank Bars in Reinforced Concrete Structures

In reinforced concrete construction, the importance of crank bars cannot be overstated. These specially bent reinforcement bars are critical in ensuring the strength, durability, and load-bearing performance of slabs, beams, and columns. Crank bars serve both structural and functional purposes by efficiently transferring stresses and minimizing chances of failure.

Let us delve into the intricate details of why crank bars are used, how they function, and where they are crucially applied.

What Are Crank Bars?

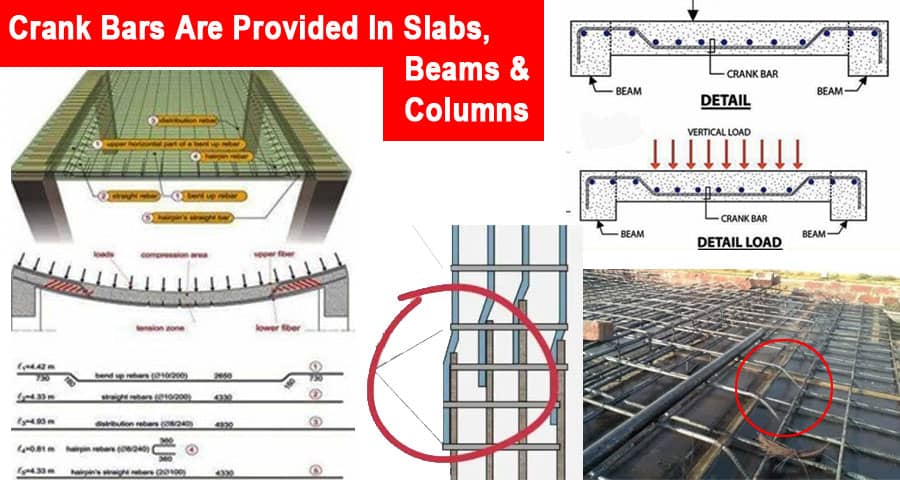

Crank bars, also known as bent up bars, are reinforcement bars (rebars) that are intentionally bent at specific angles (usually 45° or 60°) near the supports or span sections of RCC slabs and beams. These bends allow the bars to act effectively against shear forces and reduce negative bending moments.

Why Crank Bars Are Provided in Slabs

1. Counteracting Negative Moments

In slab construction, crank bars are provided at the supports to resist negative bending moments. Near the support of a simply supported slab, top fibers are in tension. A cranked bar bends up into the compression zone, thereby providing the required tensile strength at the top.

2. Economical Reinforcement Distribution

Instead of placing two separate layers of steel (top and bottom), crank bars allow alternate distribution of bars which saves steel and simplifies bar arrangement.

3. Ensuring Continuity at Supports

Crank bars provide reinforcement continuity at slab ends and supports, improving the moment resistance capacity and overall ductility of the structure.

4. Enhancing Load Transfer Efficiency

When slabs experience load from above, crank bars enhance load transfer from the middle span towards the supports by resisting tension at critical points.

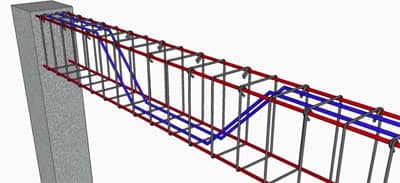

Why Crank Bars Are Used in Beams

1. To Resist Diagonal Shear Stress

Beams, especially near the supports, are subjected to diagonal tension and shear. Crank bars are bent upwards near the support, allowing them to function in the shear zone, where they help counteract shear failure.

2. Better Anchorage and Bonding

A crank or bend at the end of a reinforcement bar increases anchorage. In beams, this anchorage helps in preventing slippage of bars and increases the bonding strength between steel and concrete.

3. Reducing Excessive Sagging

In longer spans, the bottom of the beam can sag due to mid-span deflection. Crank bars placed correctly can resist these sagging forces by taking up tensile stresses more efficiently at the bottom center and compressive stresses at the supports.

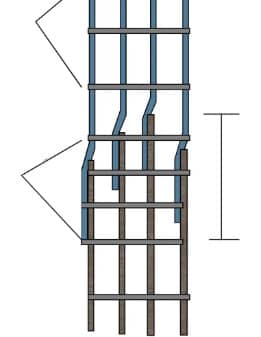

Why Crank Bars Are Used in Columns

While crank bars are not as common in columns as in slabs and beams, they are sometimes used in special circumstances.

1. Lapping in Continuous Columns

Crank bars are used when a lap splice is required in columns. The bend provides sufficient length and ensures better load transfer from one bar to another.

2. Accommodating Architectural Constraints

In certain cases, due to column offsets or eccentricities, crank bars are provided to maintain the alignment of reinforcement without compromising on structural performance.

Standard Crank Bar Specifications

To ensure structural performance and compliance with IS codes, crank bars are designed with the following parameters:

- Crank Angle: Usually 45° or 60°

- Crank Length: Typically, the crank length (or bent-up portion) is L/4 of the span, where L is the length of the slab.

- Bend Location: The bar is bent at a location 1/4th of span length from the support.

- Overlap: The cranked bars alternate, ensuring a uniform top reinforcement distribution without excessive congestion.

Advantages of Crank Bars in RCC Structures

1. Structural Strength

By efficiently distributing the tensile and shear forces, crank bars improve the overall stability and strength of the RCC structure.

2. Material Optimization

Crank bars allow engineers to avoid double layering of steel, thus reducing material usage while still meeting structural requirements.

3. Ease of Construction

Crank bars simplify the bar bending schedule (BBS) and reinforcement detailing, reducing labor and execution time.

4. Prevention of Cracks

Properly placed crank bars help reduce shear cracks near supports and control flexural cracks at mid-span.

Crank Bar Detailing in Drawings

When preparing construction drawings:

- Crank bars must be clearly indicated with bending angles, bend locations, and cut lengths.

- Cross-sectional views should show the alternate bent-up arrangement to ensure clarity during execution.

- The bar bending schedule (BBS) must reflect the exact number, shape code, and length of cranked bars for ease in fabrication.

Common Mistakes in Crank Bar Placement

- Incorrect Bend Angle: Using angles other than the specified 45°/60° can lead to ineffective load transfer.

- Improper Lapping: Overlapping cranked bars without proper anchorage reduces effectiveness.

- Lack of Cover: Not maintaining adequate cover at the bend section can expose steel to corrosion.

- Congested Reinforcement: Overuse or improper staggering leads to congestion, making concrete placement difficult.

Comparison: Cranked Bars vs Straight Bars

| Feature | Cranked Bars | Straight Bars |

|---|---|---|

| Reinforcement Efficiency | High in slabs and beams | Moderate |

| Flexural Strength | Better due to staggered tension control | Depends on placement |

| Material Optimization | Economical | May require more bars |

| Suitability for Shear Zone | Excellent | Poor without stirrups |

IS Code Provisions Regarding Crank Bars

In IS 456:2000, provision for bent-up bars in slabs and beams is well described. Clause 26.2.3.2 recommends bending alternate bars near the support to meet the moment and shear requirements efficiently. It also suggests minimum and maximum spacing, cover depth, and overlap lengths.

Conclusion

Crank bars are an indispensable element in the design of reinforced concrete structures. Their strategic placement not only improves the structural integrity but also ensures cost-effective construction. Whether in slabs, beams, or specific column arrangements, crank bars provide a simple yet powerful solution for managing the intricate balance of forces in concrete members.

Their correct usage, detailing, and understanding are vital for any structural engineer or construction professional striving for durable and efficient construction.

Please watch the following short video for Crank Bars Are Provided In Slabs, Beams and Columns