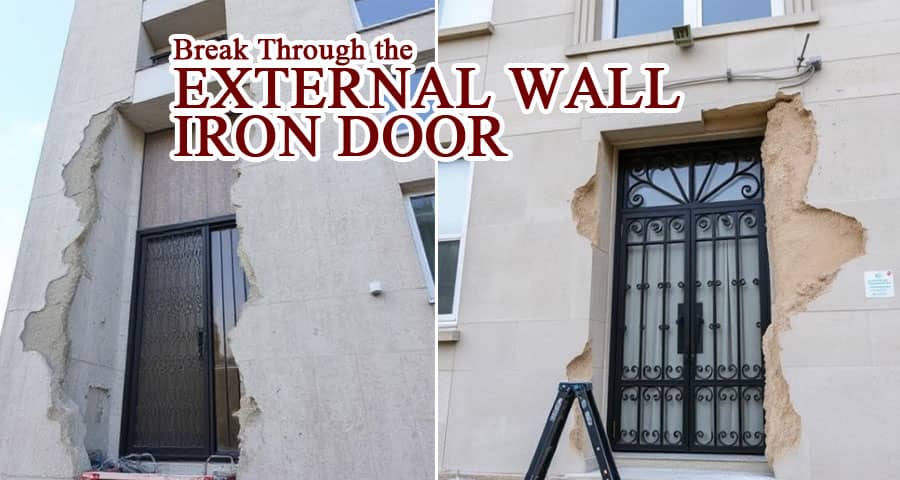

How Do You Break Through the External Wall of a Unit in a High-Rise Building to Install an Iron Door?

Understanding the Structural Composition of High-Rise Building Exterior Walls

Before any modification to a high-rise building's structure, particularly involving exterior walls, it is crucial to assess the materials used in construction. Most modern high-rise buildings use reinforced concrete, curtain walls, or masonry as exterior façade. These materials are designed to withstand wind loads, seismic activity, and provide insulation and safety. Therefore, any intervention, especially cutting through an exterior wall, must be handled with precision, compliance, and expertise.

Securing Legal Permissions and Building Approvals

Modifying an external wall, especially to install an iron door, typically requires permission from local building authorities and possibly the building management or homeowners' association (HOA). This is not just a compliance issue - unauthorized wall modifications can compromise building safety and fire escape routes.

To proceed:

- Submit engineering drawings to the local building department.

- Obtain architectural approval if the façade design is regulated.

- Coordinate with the structural engineer to ensure no compromise to load-bearing elements.

Failing to comply can result in heavy fines or forced restoration.

Conducting a Structural Assessment Before Wall Penetration

A structural engineer must inspect the site to:

- Identify load-bearing elements

- Analyze reinforcement placements (via tools like ground-penetrating radar)

- Assess utility lines (plumbing, electrical, HVAC)

This step ensures that the wall penetration for the iron door will not:

- Weaken the structure

- Interrupt utilities

- Violate safety codes

Marking and Measuring the Door Opening

Accurate measurement is critical. The door frame must fit perfectly within the designated area to maintain integrity and weatherproofing. Key steps include:

- Marking the outline of the iron door, including clearances for installation foam or mortar.

- Ensuring the height and width are level and plumb.

- Factoring in any threshold height needed for water resistance or fire-rating compliance.

Choosing the Right Tools and Equipment for Wall Cutting

Cutting through an external wall of a high-rise is a specialized process requiring:

- Concrete cutting saws with diamond blades

- Core drilling machines for precise reinforcement removal

- Dust extraction and vacuum systems

- Scaffolding or suspended platforms if access is from the outside

Using improper tools can lead to:

- Wall cracking

- Rebar damage

- Uneven cuts, compromising the iron door's alignment

Executing the Wall Penetration with Precision

This stage must be carried out by qualified professionals, ensuring:

- Safety protocols are followed

- The area is sealed to prevent dust and debris from affecting adjacent units

- A step-by-step cutting approach is taken - starting with pilot holes at the corners, followed by top-to-bottom perimeter cutting

To maintain wall stability:

- Leave temporary supports in place

- Avoid overcutting which could lead to post-installation cracks

Reinforcing the Wall Opening for Load Redistribution

Once the wall is penetrated, it's necessary to reinforce the opening to ensure:

- Structural redistribution of loads

- Edge protection for the iron door installation

This typically includes:

- Installing steel lintels or channels above the opening

- Pouring reinforced concrete bands around the frame

- Sealing all edges with expansion foam or mortar

The reinforcement must comply with engineering recommendations and pass inspection if mandated.

Installing the Iron Door Frame with Structural Anchors

Iron doors are heavy and durable, requiring firm anchoring:

- Use expansion bolts or chemical anchors rated for high loads

- Ensure the frame is square and level

- Shim the frame to prevent sagging over time

Once the frame is fixed:

- Apply non-shrink grout around the frame

- Seal all joints with weatherproofing silicone

Iron doors often include fire-rated, anti-theft, and soundproof features, so precise installation ensures full functionality.

Finishing the Installation with Sealants and Aesthetic Touches

To maintain building aesthetics and protect against environmental intrusion:

- Seal all external joints with weatherproof caulk

- Install flashing or drip edges to direct water away

- Match exterior wall color using paint or façade cladding

Internally:

- Reconstruct the surrounding wall with plaster or gypsum board

- Add trim work or metal edging for a clean look

Finishing enhances durability, appearance, and security of the door installation.

Conducting a Final Inspection and Quality Assurance

The final step includes:

- Operational check of the iron door for smooth opening and locking

- Verifying seals are tight and weatherproof

- Ensuring no gaps or misalignment

A final inspection by a certified engineer or local authority may be necessary, especially if part of the façade or fire route was altered.

Common Challenges and Professional Solutions

| Challenge | Solution |

|---|---|

| Interfering rebar | Use core drilling and reinforcement bars instead of cutting through |

| Noise and vibration impact | Schedule during non-peak hours, use low-vibration tools |

| Debris management | Use dust containment systems, conduct daily clean-up |

| Wall cracking risk | Implement pre-cut relief joints, monitor wall behavior during cutting |

Why Professional Installation Matters

Installing an iron door in a high-rise exterior wall is not a DIY task. It demands:

- Expert structural knowledge

- Proper equipment

- Understanding of local codes and permits

- Seamless coordination with building management and contractors

Hiring experienced professionals ensures compliance, safety, and longevity of the modification.

Please watch the following short video for Break Through the External Wall of a Unit in a High-Rise Building to Install an Iron Door