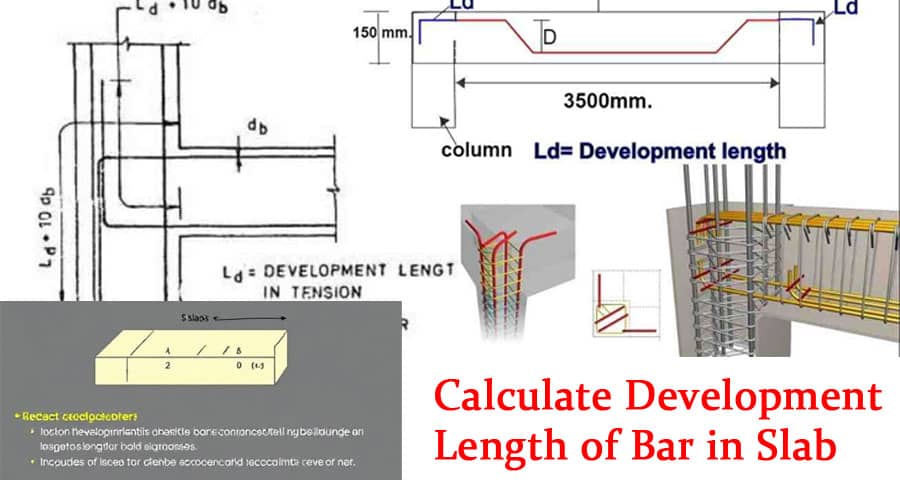

How Do I Calculate Development Length of Bar in Slab?

Understanding Development Length in Reinforced Concrete Slabs

The development length is a critical parameter in reinforced concrete design, ensuring that steel reinforcement bars (rebars) are properly anchored into the concrete to achieve full strength. In slab construction, calculating this length accurately is vital for structural integrity, crack prevention, and load transfer.

Definition of Development Length

Development length (Ld) refers to the minimum length of embedded rebar required in concrete to develop the full tensile strength of the bar. It ensures that the stress from the steel is safely transferred to the surrounding concrete through bond stress.

IS Code Guidelines for Development Length Calculation

According to IS 456:2000, the development length, Ld, for a bar in tension may be calculated using the formula:

Ld = (ɸ x ss) / (4 x tbd)

Where:

- ɸ = Nominal diameter of the bar (in mm)

- ss = Stress in the bar at the section considered at design load (usually 0.87 x fy)

- tbd = Design bond stress (in N/mm2), depending on concrete grade and bar type

Step-by-Step Calculation of Development Length

1. Identify Bar Diameter (?)

Select the nominal diameter of the rebar used in the slab. Common slab reinforcement bars range from 8 mm to 16 mm in residential and commercial constructions.

2. Determine Design Stress in Steel (ss)

For Fe 500 steel grade:

ss = 0.87 x fy = 0.87 x 500 = 435 N/mm2

Use this value unless a different steel grade is specified.

3. Get Design Bond Stress (tbd)

Refer to Table 21 of IS 456:2000, which provides tbd for various grades of concrete.

For instance:

| Concrete Grade | tbd for Plain Bars (N/mm2) | tbd for Deformed Bars (N/mm2) |

| M20 | 1.2 | 1.6 |

| M25 | 1.4 | 1.9 |

| M30 | 1.5 | 2 |

For deformed bars (commonly used in slabs), apply a factor of 1.25 over plain bars.

Example Calculation

Given:

- Bar diameter = 12 mm

- Concrete grade = M25

- Type of bar = Deformed

- Steel grade = Fe 500

Step 1: ss = 0.87 x 500 = 435 N/mm2

Step 2: tbd = 1.9 N/mm2 (for deformed bars in M25 concrete)

Development Length (Ld)

Ld = (? x ss) / (4 x tbd)

Ld = (12 x 435) / (4 x 1.9)

Ld = 5220 / 7.6

Ld ≈ 686.84 mm

So, a minimum of 687 mm of bar length must be embedded in the concrete to ensure full development.

Development Length in Compression

For bars in compression, the bond stress is increased by 25%, and the formula remains the same.

tbd (compression) = tbd x 1.25

So for the same M25 concrete and deformed bar:

tbd = 1.9 x 1.25 = 2.375 N/mm2

Then: Ld (compression) = (12 x 435) / (4 x 2.375)

Ld = 5220 / 9.5

Ld ≈ 549.47 mm

Hooks and Bends Contribution in Development Length

In cases where space constraints or detailing limitations restrict straight development, hooks and bends can be used.

- A standard 90° bend provides anchorage equivalent to 8ɸ

- A 180° hook provides anchorage of 16ɸ

These values can be added to the available development length when calculating effective anchorage.

Minimum Anchorage Length

According to IS 456, the minimum anchorage length shall not be less than:

Development length (Ld) OR 12ɸ, whichever is greater

Always ensure that the anchorage provided exceeds these minimums to avoid structural failures.

Practical Considerations for Slab Detailing

- Ensure proper cover to reinforcement (typically 15 - 25 mm for slabs)

- Avoid lapping bars at points of maximum stress unless sufficient development length is available

- Provide extra bar lengths beyond the support when detailing corner bars or top bars in cantilevers

- Use mechanical couplers or welding if bar length is insufficient

Influence of Bar Spacing and Slab Depth

- Closely spaced bars in thinner slabs might necessitate a reduction in bar diameter to maintain required development length.

- In thin slabs, use longer bends or hooks when full straight development length isn't feasible.

Using Software and Design Tools

Advanced software like STAAD.Pro, ETABS, or AutoCAD Structural Detailing can automatically calculate and verify development lengths based on bar properties and concrete grade. However, manual verification is always recommended for critical sections.

Key Takeaways

- Always calculate development length based on actual bar diameter, concrete grade, and type of bar.

- Ensure that the full Ld is provided within the slab span or via bends/hooks.

- Check IS 456:2000 tables and clauses for updated bond stress values.

- Never compromise on anchorage length - it is crucial for the load transfer mechanism.

Please watch the following short video for Calculate Development Length of Bar in Slab