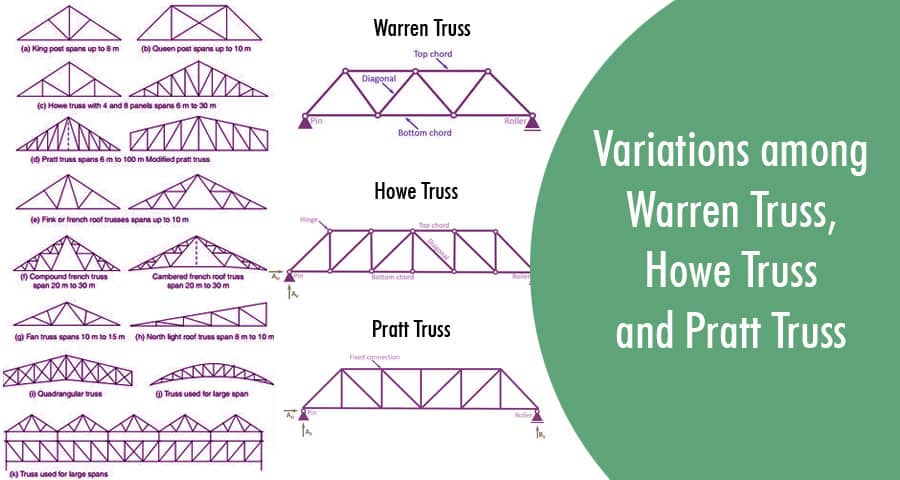

Variations among Warren Truss, Howe Truss and Pratt Truss

In the world of civil engineering, trusses play a fundamental role in the design of bridges and other structures, offering stability, strength, and efficiency. Three prominent types of trusses - Warren Truss, Howe Truss, and Pratt Truss - are frequently utilized, each with distinct design characteristics, load distribution mechanisms, and structural applications.

Overview of the Trusses: Warren, Howe, and Pratt

Trusses are load-bearing structures composed of triangular units, designed to spread the weight evenly across a wide area. The Warren Truss, Howe Truss, and Pratt Truss each have unique design frameworks. These truss systems differ in their arrangement of diagonals and vertical members, influencing how they handle forces such as compression and tension.

Warren Truss: Efficiency Through Simplicity

The Warren Truss is characterized by its equilateral or isosceles triangle pattern. In this type of truss, the diagonal members alternate between tension and compression forces under a uniformly distributed load. This alternating pattern is one of the main features that set the Warren Truss apart. Its design is simple, with fewer components compared to other trusses, which translates to less material used and lower costs.

- Advantages: The simplicity of the Warren Truss allows for efficient load distribution, making it suitable for longer spans. The absence of vertical members in some variations can further reduce weight and complexity.

- Applications: This type of truss is commonly used in railway bridges, pedestrian bridges, and roof support systems, where evenly distributed loads are prevalent.

Howe Truss: A Classic in Compression-Dominated Designs

The Howe Truss is distinctive for its diagonals that slope toward the center of the span, with vertical members supporting the horizontal beams. The diagonals experience compression, while the vertical members handle tension. This unique combination makes the Howe Truss particularly strong when dealing with loads from above.

- Advantages: The Howe Truss excels in situations where a structure needs to support heavy loads. The compression-dominated diagonals help in stabilizing longer spans, particularly in wooden bridges, which were commonly constructed in the 19th century.

- Applications: Often employed in highway bridges, railroad bridges, and large-scale roof structures, the Howe Truss is favored for situations where heavy loads and large spans are critical design considerations.

Pratt Truss: Efficiency in Tension-Dominated Designs

The Pratt Truss, which is visually similar to the Howe Truss but with opposite force distribution, features diagonals that slope outward from the center of the span. In this design, the diagonal members are in tension, while the verticals experience compression. The tension-dominated design makes the Pratt Truss a popular choice for a variety of bridge types, especially where variable loads are common.

- Advantages: The Pratt Truss is efficient in managing dynamic or fluctuating loads, as the tensioned diagonals offer better resistance to such forces. It also allows for easy fabrication, making it a cost-effective solution for large bridges.

- Applications: The Pratt Truss is widely used in long-span bridges, industrial buildings, and structural frameworks that face varying load conditions, such as railway or highway bridges.

Key Differences Among Warren, Howe, and Pratt Trusses

Force Distribution

One of the most critical distinctions between these truss types lies in how they handle forces.

- Warren Truss: Alternates between tension and compression in its diagonal members, which makes it well-suited for uniformly distributed loads.

- Howe Truss: Handles compression in the diagonals and tension in the verticals, making it ideal for load-bearing situations from above.

- Pratt Truss: Manages tension in the diagonals and compression in the verticals, which allows it to efficiently deal with fluctuating and dynamic loads.

Materials and Design Considerations

The choice between these trusses often depends on the type of material being used and the specific design requirements.

- Warren Truss: Its simplicity and fewer members make it a popular choice for steel or aluminum bridges, where material costs need to be minimized.

- Howe Truss: Originally used for timber bridges, this design remains effective when heavy loads are involved, especially in large wooden or composite structures.

- Pratt Truss: Commonly constructed using steel, its tension-based design makes it versatile for modern applications, particularly where load conditions can change.

Span Length

- Warren Truss: Best suited for medium to long spans where even load distribution is essential.

- Howe Truss: Typically used for longer spans that require additional support for heavy, static loads.

- Pratt Truss: Often chosen for long spans where the load may fluctuate, such as in railway bridges or industrial applications.

Cost Efficiency

When considering the cost of materials and labor, the Warren Truss is often the most cost-effective due to its simpler design and reduced material usage. However, the choice of truss also depends on the specific requirements of the project, with Howe Truss being more expensive but ideal for heavy loads, and the Pratt Truss offering a balance between cost and performance in fluctuating load environments.

Structural Applications in Modern Engineering

Each of these truss types continues to play an essential role in modern engineering. While Warren Trusses are often seen in lightweight applications like roof structures and pedestrian bridges, Howe Trusses are still preferred for heavy-duty use, particularly in timber bridges and large-scale constructions. The Pratt Truss remains a favorite for railway and highway bridges due to its versatility in handling dynamic loads.

In more recent designs, engineers may combine elements from different trusses to create hybrid structures that optimize performance. For example, a combination of Warren and Pratt elements can enhance load distribution while maintaining the structural simplicity of the Warren Truss.

Conclusion: Choosing the Right Truss

When selecting between the Warren Truss, Howe Truss, and Pratt Truss, engineers must consider several factors, including the type of load, span length, material, and cost. Each truss has its strengths and limitations, with the Warren Truss excelling in simplicity and cost-efficiency, the Howe Truss in supporting heavy static loads, and the Pratt Truss in managing variable loads over long spans.

Ultimately, the choice depends on the specific requirements of the project. However, understanding the key differences among these trusses allows for better decision-making and ensures the creation of structures that are not only efficient but also durable and cost-effective.

For more information, please watch the video tutorial